|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

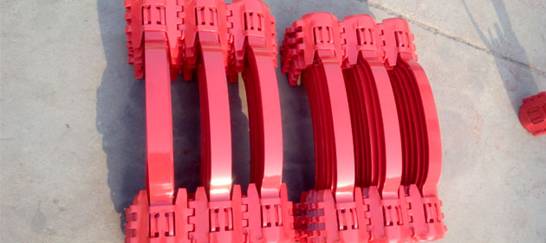

| Casing Centrializer |

|

Bow spring centrializer:

Description:

Super-strength spring steel is applied to centralize casing in wellbore,and improve cementing quality.

Feature:

1ĄąEvery attachment is pressed into shape by moulding instead of welding and rivet.

2Ąą3-section structure for easy transport.

3ĄąStarting force and restoring force conform to API standards.

4ĄąEasy-and-convenient to use.

5ĄąAlternative turbulence plates can effectively improve displacement efficiency.

Specification:

Rigid centralizer:

Description:

It makes the casing centralized in wellbore and improves cementing quality.

Features:

1.Spiral blades increase annular turbulence.

2.With its stream-lined shape,it enables casing to run easily in wellbore.

Roller centralizer:

Integral centralizer:

Description:

Revolutionary centralizer design for highly deviated, horizontal ERD wells. One-piece integral unit has no weak point. ItĄŻs extremely robust and also tolerant to under gauge hole conditions.

Feature:

1. Integral steel plate 2. High temperature wire saw welding

3. Laser cutting 4. Bow centralizer be Hydroform

5. Heat treatment 6. Powder coating processing

PRODUCT SUPERIORITY

1. Processing technology of high precision meet the requirements of various size hole

2. Down, there is no initial resistance, low friction, low torque

3. Centered, enhanced string restoring force

4. Weak spot, high strength, no stress, high reliability

5. Without any separation of welding components or parts, eliminate the possibility of salvage

6. its elasticity can meet down into reducing interval

7. All the indexes exceed the standard API lifter

8. Article, straight centralizer design maximum casing running efficiency

9. Article, centralizer design and casing is a good joint, casing protection

Glider centralizer:

DescriptionŁș

Spiral centralizer has a smooth angle between spiral righting slip and axis, is superior than conventional straight edge style: Firstly, when down into the hole and meet irregular borehole diameter there will be lateral component created on spiral centralizer by the wall of hole which can reduce the resistance to impact; Secondly, There will be Swirl flow out of the centralizer when cement slurry through the spiral sheet, get smooth, washed wall virtual mud cake, Whirl flow length is 7-9m, the best distance is 3-4m near the centralizer nearby, which can improve the displacement efficiency of cement slurry, which is very beneficial for improving cementing quality.

Feature:

Spiral centralizer has a smooth angle between spiral righting slip and axis, is superior than conventional straight edge style: Firstly, when down into the hole and meet irregular borehole diameter there will be lateral component created on spiral centralizer by the wall of hole which can reduce the resistance to impact; Secondly, There will be Swirl flow out of the centralizer when cement slurry through the spiral sheet, get smooth, washed wall virtual mud cake, Whirl flow length is 7-9m, the best distance is 3-4m near the centralizer nearby, which can improve the displacement efficiency of cement slurry, which is very beneficial for improving cementing quality.

|

Casing Spec.

|

Hole Size

|

Max.O.D.

|

|

mm

|

in

|

mm

|

in

|

|

4-1/2

|

6

|

146.1

|

5.752

|

|

5

|

6-1/2

|

158.8

|

6.252

|

|

5-1/2

|

8-1/2

|

209.6

|

8.252

|

|

7

|

8-1/2

|

209.6

|

8.252

|

|

7-5/8

|

9-1/2

|

235

|

9.252

|

|

9-5/8

|

12-1/4

|

304.8

|

12.000

|

|

10-3/4

|

12-1/4

|

304.8

|

12.000

|

|

13-3/8

|

16

|

400

|

15.748

|

|

13-3/8

|

17-1/2

|

438

|

17.244

|

|

|

PreviousŁș

Stop collar

NextŁș

Casing Packer

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|