|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Submersible slurry pump |

|

GMZ series Slurry pump

• Flow: 8-2600 m3/h • Flow: 8-2600 m3/h

• Head:9-110m

• Matched power:3-630kW

• Medium concentration:mortar 45%,pulp 50%

• Seal form:mechanical seal and packing seal

• Flow passage component:High chromium wear-resistant allo

As a single stage single suck and axial sucking cantilever horizontal centrifugal pump, the GMZ series slurry pump can be applied to many industries, such as metallurgyĄąmineĄąelectric powerĄądesulfurizationĄąaeroconcreteĄąchemical engineering and so on. This pump can be used for conveying the corrosive slurry with large quantity solid material.

1ĄąThe flow components of GMZ slurry pump adopt high strength and wear resistant material, so it applies to deep-etching Ąąhigh concentration and large particle slurry, and within the maximum working pressure, this pump can be used in multilevel series .

2ĄąAccording to different sucking medium, the GMZ slurry pump can be changed with different flow components, generally, there are wear-resistant alloy Cr26ĄąCr 28ĄąNo.2 wear-resistantĄąA49ĄąCD4. For the feature of high content chlorine liquid ion in flue gas desulfurization flurry, our company introduced wear-resistant and anticorrosion Cr30, which is the most advanced around the world, from France, in Cr30, the MoĄąCrĄąCuĄąN as well as a certain active elements, it has excellent anti scour as well as better strength and toughness.

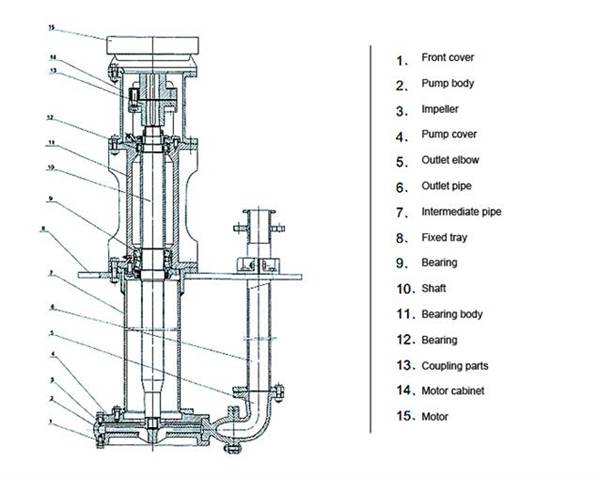

YZ vertical slurry Pump

YZ vertical slurry Pump is the cantilever pump structure of single stage and single suction, with the bearing housing, supporting, intermediate pipe connecting the pump hydraulic components, the water is discharged out from the drain pipe parts, pump impeller is for semi-shrouded with the agitating vane on the vane extended, the main characteristic of this pump is the underwater pump shaft parts have enough rigidity, the impeller and pump shell have no bearings, no shaft seal, which can transport the greater medium of solid particles. The length of inserting the water by pump is between 800 and 2000, the suction pipe can be matched in case of need. The shaft seal runs into the underwater pump without setting up the shaft seal, drive should be installed the vertical motor on the supporting seat connecting with coupling and pump. YZ vertical slurry Pump is the cantilever pump structure of single stage and single suction, with the bearing housing, supporting, intermediate pipe connecting the pump hydraulic components, the water is discharged out from the drain pipe parts, pump impeller is for semi-shrouded with the agitating vane on the vane extended, the main characteristic of this pump is the underwater pump shaft parts have enough rigidity, the impeller and pump shell have no bearings, no shaft seal, which can transport the greater medium of solid particles. The length of inserting the water by pump is between 800 and 2000, the suction pipe can be matched in case of need. The shaft seal runs into the underwater pump without setting up the shaft seal, drive should be installed the vertical motor on the supporting seat connecting with coupling and pump.

Spareparts for slurry pump

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/14 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|