|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

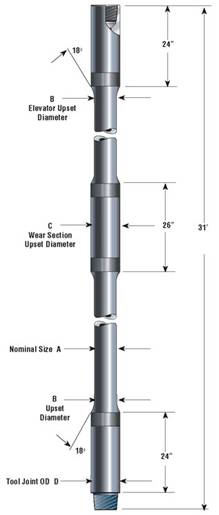

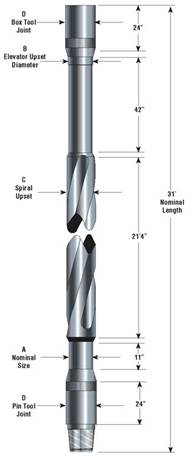

| Heavy Weight Drill Pipe |

The Heavy Weight Drill Pipe is made from one piece of AISI 4145H solid bar, fully heat-treated, all physical properties confirm with API Spec 7 Latest Editions The Heavy Weight Drill Pipe is made from one piece of AISI 4145H solid bar, fully heat-treated, all physical properties confirm with API Spec 7 Latest Editions

The wear-resistance hardbanding is standard on tool joints connections and central upset Hardbanding is made by an automatic machine after preheating the pipe and is followed by stress relieving

The Type of handbanding include Iron-Matrix powder alloy, Tungsten Carbide particle, and Arnco 100XT

Standard Bands:

one 4" wear band on both pin and box ends, plus one 1" band on 18 degree shoulder of box

Two 3" wear bands on central upsets

The hardbanding is completing flush on both joints and 1/8" oversize on the central upset (full flush on request)

Internal Coating: The HWDP could be internally coated with DPC (Equivalent to TK34) as customers request which are able to prevent corrosion and extend life

Order Instruction:

Nominal Size

Range

Hardbanding type

Internal coating if required

Extra-long tool joints if required

API Stress relief recess

|

Integral Heavy Weight Dirll Pipe Spec

|

|

Nom Size (in)

|

Approx Overall Length (ft)

|

Tool Joints

|

Tube

|

Approx Weight

|

Make-up Torque (lb-ft)

|

|

OD (in)

|

ID (in)

|

Conn

|

Center upset OD (in)

|

Center upsets end (in)

|

ID (in)

|

Center upset length (in)

|

lb/ft

|

kg /jts

|

|

3 1/2

|

30 5

|

4 3/4

|

2 1/16

|

3 1/2IF

|

4

|

3 5/8

|

2 1/16

|

24

|

25 3

|

350

|

11,500

|

|

4

|

30 5

|

5 1/4

|

2 1/2

|

4 FH

|

4 1/2

|

4 1/8

|

2 1/2

|

24

|

29 5

|

410

|

17,300

|

|

4 1/2

|

30 5

|

6 1/4

|

2 13/16

|

4IF

|

5

|

4 5/8

|

2 13/16

|

24

|

41

|

565

|

25,500

|

|

5

|

30 5

|

6 1/2~6 5/8

|

3

|

4 1/2IF

|

5 1/2

|

5 1/8

|

3

|

24

|

49 3

|

681

|

34,000

|

|

5 1/2

|

30 5

|

7~7 1/4

|

3 5/8

|

5 1/2 FH

|

6

|

5 11/16

|

3 5/8

|

24

|

55

|

760

|

38,000

|

|

6 5/8

|

30 5

|

8~8 1/4

|

4

|

6 5/8 FH

|

7 1/4

|

6 3/4

|

4

|

24

|

70

|

970

|

55,800

|

|

Integral Spiraled Heavy Weight Drill Pipe

|

|

Nom

Size

(in)

|

Approx

Overall

Length (ft)

|

Tool Joints

|

Tube

|

Approx Weight

|

Make-up

Torque

(lb-ft)

|

|

OD (in)

|

ID (in)

|

Conn

|

Center upset OD (in)

|

Center upsets end (in)

|

ID (in)

|

Center upset length (in)

|

lb/ft

|

kg /jts

|

|

3 1/2

|

30 5

|

4 3/4

|

2 1/16

|

3 1/2IF

|

4

|

3 5/8

|

2 1/16

|

18 5

|

28

|

387

|

11,500

|

|

4

|

30 5

|

5 1/4

|

2 1/2

|

4 FH

|

4 1/2

|

4 1/8

|

2 1/2

|

18 5

|

33

|

457

|

17,300

|

|

4 1/2

|

30 5

|

6 1/4

|

2 13/16

|

4IF

|

5

|

4 5/8

|

2 13/16

|

18 5

|

45

|

623

|

25,500

|

|

5

|

30 5

|

6 1/2~6 5/8

|

3

|

4 1/2IF

|

5 1/2

|

5 1/8

|

3

|

18 5

|

54

|

748

|

34,000

|

|

5 1/2

|

30 5

|

7~7 1/4

|

3 5/8

|

5 1/2 FH

|

6

|

5 11/16

|

3 5/8

|

18 5

|

62

|

858

|

38,000

|

|

6 5/8

|

30 5

|

8~8 1/4

|

4

|

6 5/8 FH

|

7 1/4

|

6 3/4

|

4

|

18 5

|

76

|

1052

|

55,800

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|