|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Drilling Jar |

|

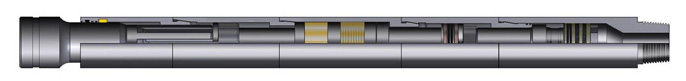

Mechanical Drilling Jar

The mechanical drilling jar type JZ takes the appliance of mechanical structure And high pressure will not produce in inner chamber as to create a good sealing property and greatly extend the service life During the drilling operation, the jarring mechanism has no action due to its unique structure which can not be controlled by the common drilling condition and torque, and its unique structure can accurately transmit the torque Moreover, the up or down jarring blow is adjustable prior to tripping in and will not change during the downhole operation so as to keep a constant jarring load

|

Specification Series and Performance Parameters

|

|

TYPE

|

O D

mm

(in )

|

I D

mm

(in )

|

Connection

API

|

Max Tensile Load

MN

(Lbf)

|

Max Working torque

k NĄ€m

(LbfĄ€m)

|

Pumping area

cm2

|

Up jarring stroke

mm

(in )

|

Down jarring stroke

mm

(in )

|

Overall length

( locked)

mm

(in )

|

|

JZ95

|

95

(3 3/4)

|

28

(1 1/8)

|

2 7/8REG

|

0 5

(112500)

|

5

(1,125)

|

32

|

200

(7 87)

|

200

(7 87)

|

5 800

(228 35)

|

|

JZ108

|

108

(4 1/4)

|

36

(1 7/16)

|

NC31

|

0 7

(157500)

|

10

(2,250)

|

38

|

203

(8 00)

|

203

(8 00)

|

6 404

(252 13)

|

|

JZ121

|

121

(4 3/4)

|

51 4

(2)

|

NC38

|

1 0

(225000)

|

12

(2,700)

|

60

|

198

(7 80)

|

205

(8 07)

|

6 343

(249 72)

|

|

JZ159ąó

|

159

(6 1/4)

|

57

(2 1/4)

|

NC46

|

1 5

(337500)

|

14

(3,150)

|

100

|

149

(5 87)

|

166

(6 54)

|

6 517

(256 57)

|

|

JZ165

|

165

(6 1/2)

|

57

(2 1/4)

|

NC50

|

1 6

(360000)

|

14

(3,150)

|

100

|

149

(5 87)

|

166

(6 54)

|

6 517

(256 57)

|

|

JZ178

|

178

(7)

|

57

(2 1/4)

|

NC50

|

1 8

(405000)

|

15

(3,150)

|

100

|

147 5

(5 81)

|

167 5

(6 59)

|

6 570

(258 66)

|

|

JZ203

|

203

(8)

|

71 4

(2 13/16)

|

6 5/8REG

|

2 2

(495000)

|

18

(4,050)

|

176

|

144 5

(5 69)

|

176 5

(6 95)

|

7 234

(284 80)

|

|

JZ229

|

229

(9)

|

76

(3)

|

7 5/8REG

|

2 5

(562500)

|

22

(4,950)

|

181

|

203

(8 00)

|

203

(8 00)

|

7 753

(305 24)

|

Full Hydraulic Drilling Jar

The full hydraulic drilling jar type QY is a double-acting hydraulic jar and is used to free equipment stuck down hole It can be used with a down hole motor, because it is capable of torque transmission, and is ideal for use in coiled tubing operations, snubbing, rotary drilling and fishing applications By adjusting the amount of surface push or pull (no torque or external adjustments are required) the operator can deliver very light or maximum impacts in either direction

|

Specification Series and Performance Parameters

|

|

Type

|

O D

mm(in )

|

Water Hole

mm(in )

|

Overall Stroke

mm(in)

|

Max Up

Jarring Load

kN(lbf)

|

Max Down Jarring Load

kN(lbf)

|

Connection

API

|

Max Tensile

load

KN(lbf)

|

Max Working Torque

kNĄ€m

|

|

QY121

|

121

(4 3/4)

|

51 4

(2)

|

9442

|

350

Łš78000Ł©

|

180

(40000)

|

NC38

|

1000

(225000)

|

3 5

(2580)

|

|

QY159

|

159

(6 1/4)

|

69

(2 23/32)

|

10323

|

700

Łš160000Ł©

|

350

(78000)

|

NC46

|

1500

(337000)

|

14

(10300)

|

|

QY165

|

165

(6 1/2)

|

69

(2 23/32)

|

10323

|

700

Łš160000Ł©

|

350

(78000)

|

NC46

|

1500

(337000)

|

14

(10300)

|

|

QY178

|

178

(7)

|

69

(2 23/32)

|

9850

|

800

Łš180000Ł©

|

400

(90000)

|

NC50

|

1800

(405000)

|

15

(11000)

|

|

QY203

|

203

(8)

|

76

(3)

|

10261

|

1000

Łš225000Ł©

|

500

(120000)

|

6 5/8REG

|

2200

(495000)

|

18

(13000)

|

|

QY241

|

241

(9 1/2)

|

76 2

(3)

|

9987

|

1200

Łš270000Ł©

|

600

(135000)

|

7 5/8REG

|

2500

(562000)

|

22

(16000)

|

Hydro-mechanical Drilling Jar

The hydro mechanical drilling jar type ZXJ can be used either independently or in conjunction It is designed for use during drilling operations to apply an intensified force either up or down against a stuck portion of the drilling string Its unique design combines both a hydraulic time delay release and a mechanical latch mechanism, in one relatively short, double acting drilling jar Therefore, it is an ideal tool for drilling directional well, complicated well and slant well

|

Specification Series and Performance Parameters

|

|

Type

|

ZXJ36

|

ZXJ46

|

ZXJ 56

|

ZXJ 62ąò

|

ZXJ 64

|

ZXJ 70

|

ZXJ 76

|

ZXJ 80

|

|

OD mm (in )

|

95

(3 3/4)

|

121

(4 3/4)

|

146

(5 3/4)

|

159

(6 1/4)

|

165

(6 1/2)

|

178

(7)

|

197

(7 3/4)

|

203

(8)

|

|

ID mm (in )

|

28

(1 1/10)

|

51

(2)

|

57

(2 1/4)

|

57

(2 1/4)

|

57

(2 1/4)

|

70

(2 3/4)

|

71 4

(2 4/5)

|

71 4

(2 4/5)

|

|

Connection API

|

27/8REG

|

NC38

|

41/2FH

|

NC46

|

NC50

|

NC50

|

65/8REG

|

65/8REG

|

|

Max Tensile Load MN

|

0 5

|

1 0

|

1 2

|

1 5

|

1 6

|

1 8

|

2 0

|

2 2

|

|

Max Working Torque KNĄ€m

|

3 5

|

12

|

13

|

14

|

14

|

15

|

16

|

18

|

|

Max Upward Jarring Load kN

|

160

|

280

|

400

|

560

|

560

|

640

|

800

|

800

|

|

Max Upward Jarring Stroke mm (in)

|

254

(10)

|

305

(12)

|

330

(13)

|

346

(13 62)

|

346

(13 62)

|

346

(13 62)

|

370

(14 56)

|

370

(14 56)

|

|

Max Downward Jarring Load kN

|

100

|

220

|

300

|

420

|

420

|

480

|

600

|

600

|

|

Max Downward Jarring Stroke mm(in)

|

178

(7)

|

182

(7 16)

|

182

(7 16)

|

182

(7 16)

|

182

(7 16)

|

182

(7 16)

|

181

(7 12)

|

181

(7 12)

|

|

Max Working Temperature Ąæ

|

150

|

150

|

120

|

120

|

120

|

120

|

120

|

120

|

|

Sealing Pressure MPa

|

30

|

30

|

30

|

30

|

30

|

30

|

30

|

30

|

|

Overall Length of Up mm (in)

|

4 162

(163 85)

|

6 093

(239 88)

|

5 410

(213)

|

6 394

(251 73)

|

6 736

(265 2)

|

6 354

(250 15)

|

6 295

(247 83)

|

6 222

(244 96)

|

|

Overall Length of Down mm (in)

|

3 275

(128 93)

|

5 138

(202 28)

|

5 000

(196 9)

|

5 371

(211 45)

|

5 457

(214 8)

|

5 457

(214 8)

|

5 244

(206 45)

|

5 249

(206 65)

|

Drilling Bumper Sub

The drilling bumper sub type ZKX mainly makes the down jarring blow operation, releasing the stuck accident such as the sticking, land filling and keyway effectively and so on Moreover, it can be also used for fishing operation, or it can be considered as "heave compensator" during offshore drilling

|

Specification Series and Performance Parameters

|

|

Type

|

Tool O D

mmŁšinŁ©

|

Hole Diameter

mmŁšinŁ©

|

Connection

API

|

Overall Stroke

mm(in)

|

Max Working Load

kN(lbf)

|

Max Working Torque

kN m

|

Max Tensile Load

kN(lbf)

|

|

ZKX46

|

121(4 3/4)

|

50(2)

|

NC38

|

508(20)

|

350(79000)

|

8(5900)

|

900(202000)

|

|

ZKX76

|

197(7 3/4)

|

76(3)

|

6 5/8REG

|

1520(59 7/8)

|

770(173000)

|

15(11000)

|

1800(404000)

|

|

ZKX90

|

229(9)

|

76(3)

|

7 5/8REG

|

1520(59 7/8)

|

1300(292000)

|

20(15000)

|

2200(494000)

|

Drilling Accelerator

The drilling accelerator type ZJQ is run in conjunction with a hydraulic drilling jar of the same size, and is manufactured from high strength alloy steel The tool can not only strengthen the jarring force, but also can absorb much of the jarring shock from the rebounding string to protect tools and strings from damage

|

Specification Series and Performance Parameters

|

|

Type

|

O D

mm

(in)

|

Hole Diameter

(in)

|

Connection API

|

Max Working Stroke mm

(in)

|

Seal Pressure Mpa

|

Max Working Load

KN

|

Max Working Torque KN M

|

Overall Length mm

(in)

|

|

ZJQ

46

|

121

(4 3/4)

|

50

(2)

|

NC38

|

350

(13 78)

|

30

|

350

(78750)

|

8

(5900Ł©

|

7430

(292 5)

|

|

ZJQ

62

|

159

(6 1/4)

|

57

(2 1/4)

|

NC50

|

350

(13 78)

|

30

|

700

(157500)

|

13

(9600)

|

7780

(306 3)

|

|

ZJQ

64

|

165

(6 1/2)

|

57

(2 1/4)

|

NC50

|

350

(13 78)

|

30

|

750

(168750)

|

14

(10400)

|

7780

(306 3)

|

|

ZJQ

76

|

197

(7 3/4)

|

61 9

(2 2/5)

|

6 5/8REG

|

350

(13 78)

|

30

|

1000

(225000)

|

18

(13300)

|

7630

(300 4)

|

|

ZJQ

80

|

203

(8)

|

76 2

(3)

|

6 5/8REG

|

350

(13 78)

|

30

|

1000

(225000)

|

18

(13300)

|

7752

(305 2)

|

|

ZJQ

95

|

241

(9 1/2)

|

76

(3)

|

7 5/8REG

|

350

(13 78)

|

30

|

1200

(270000)

|

22

(16300)

|

6752

(265 8)

|

Double-acting Mechanical-hydraulic Drilling Jar

The double acting mechanical-hydraulic drilling jar type JYQ is designed for drilling operation to apply an intensified force either up or down against a stuck portion of the drilling string It incorporates the feature of both hydraulic and mechanical drilling jars, without of the inherent disadvantage of either type Its unique design combines both a hydraulic time delay release and mechanical latch mechanism in one relatively short, double acting drilling jar

|

Specification Series and Performance Parameters

|

|

Type

|

O D

mm

(in)

|

I D

mm

(in)

|

Tool Joint

Connection

API

|

Up Stroke mm

(in)

|

Down Stroke

mm

(in)

|

Working Torque

kN m

(Lb ft)

|

Max Tensile Load

kN

(Lbf)

|

Max up Jarring

KN

(Lbf)

|

Max down Jarring

KN

(Lbf)

|

Overall Length

mm

(in)

|

Piston areas

mm2

|

|

JYQ121

|

124

(4 7/8)

|

50 8

(2)

|

NC38

|

227

(8 9)

|

102

(4)

|

12 5

(21000)

|

1300

(362000)

|

250

(56250)

|

200

(45000)

|

4500

(177)

|

2516

|

|

|

121

(4 3/4)

|

57 2

(2 1/4)

|

NC38

|

227

(8 9)

|

102

(4)

|

12 5

(21000)

|

1300

(362000)

|

250

(56250)

|

200

(45000)

|

4500

(177)

|

2827

|

|

JYQ159

|

159

(6 1/4)

|

57

(2 1/4)

|

NC46

|

230

(9)

|

152

(6)

|

15

(21000)

|

2220

(730000)

|

600

(135000)

|

330

(74250)

|

5007

(197)

|

6446

|

|

JYQ165

|

165

(6 1/2)

|

70

(2 3/4)

|

NC50

|

230

(9)

|

152

(6)

|

15

(21000)

|

2220

(730000)

|

600

(135000)

|

330

(74250)

|

5007

(197)

|

6446

|

|

JYQ178

|

178

(7)

|

70

(2 3/4)

|

NC50

|

230

(9)

|

152

(6)

|

18

(25200)

|

2220

(730000)

|

600

(135000)

|

330

(74250)

|

5007

(197)

|

6446

|

|

JYQ203

|

203

(8)

|

76 2

(3)

|

65/8REG

|

232

(9 1)

|

152

(6)

|

25

(35000)

|

2500

(1000000)

|

800

(180000)

|

400

(90000)

|

5095

(200)

|

9170

|

|

JYQ241

|

241

(9 1/2)

|

76 2

(3)

|

75/8REG

|

232

(9 1)

|

152

(6)

|

50

(70000)

|

5400

(2160000)

|

1400

(315000)

|

460

(103500)

|

5300

(208)

|

172

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|