|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Elevator |

|

Drill pipe elevator Drill pipe elevator

1.DD center latch drill pipe elevators are conventional center door elevators for handling square shoulder drill pipes in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 100t(1350kN) to 500t(4500kN), and cover pipe sizes from 2⅜EU to 5½IEU; OD, IU, EU, or IEU. link ears conform to API elevator links, center Door drill pipe elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

|

Specifications

|

Bore Diameter(mm)

|

Applicable for drill pipes

|

Rating load

tonŁškNŁ©

|

|

Upper

|

Lower

|

SpecŁšinŁ©

|

SizeŁšmmŁ©

|

Bottleneck O.D. ŁšmmŁ©

|

|

DD2⅜EU(63*69)

|

68.66

|

62.31

|

2⅜EU

|

62.31

|

65.89

|

100t(900kN)

150t(1350kN)

250t(2250kN)

350t(3150kN)

500t(4500kN)

|

|

DD2⅞EU(76*86)

|

85.73

|

76

|

2⅞EU

|

73.03

|

80.96

|

|

DD3½EU(92*103)

|

103.19

|

92

|

3½EU

|

88.90

|

98.43

|

|

DD4IU(105*110)

|

109.54

|

105

|

4IU

|

101.60

|

104.78

|

|

DD4EU(105*118)

|

118.00

|

105

|

4EU

|

101.60

|

114.30

|

|

DD4½EU(118*122)

|

122.24

|

118

|

4½IU

|

114.30

|

117.48

|

|

DD4½IEU(118*131)

|

131.00

|

118

|

4½EU

|

114.30

|

127.00

|

|

DD5IEU(131*135)

|

134.94

|

131

|

5IEU

|

127.00

|

130.18

|

|

DD5½IEU(144*149)

|

149.23

|

144

|

5½IEU

|

139.70

|

144.46

|

Note:ąÙIU means internal upset,EU means external upset,IEU means internal and external upset.

ąÚAny elevator can be selected from the max load series listed in above chart.

2.DDZ center latch bottleneck drill pipe elevators are conventional center door elevators for handling taper shoulder drill pipes in oil and gas drilling operation,the elevators are cast from high quality alloy steel,heat-treated, and NDT tested. the rated loads rang from 585kN to 4500kN,and cover pipe sizes from 2⅜EU to 6⅝IEU; OD, IU, EU, or IEU. link ears conform to API elevator links, the drill pipe elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

|

Specification

|

Bore Diameter(mm)

|

Applicable for drill pipes

|

Rating load

tonŁškNŁ©

|

|

SpecŁšinŁ©

|

SizeŁšmmŁ©

|

Bottlennck O.D.ŁšmmŁ©

|

|

DDZ 2⅜EU(67)

|

67.47

|

2⅜EU

|

60.33

|

65.09

|

65t(585kN)

100t(900kN)

150t(1350kN)

200t(1800kN)

250t(2250kN)

350t(3150kN)

500t(4500kN)

|

|

DDZ 2⅞EU(83)

|

83.34

|

2⅞EU

|

73.03

|

80.96

|

|

DDZ 3½EU(67)

|

100.81

|

3½EU

|

88.90

|

98.43

|

|

DDZ4IU(109)

|

108.74

|

4IU

|

101.60

|

106.36

|

|

DDZ4EU(121)

|

121.44

|

4EU

|

101.60

|

114.30

|

|

DDZ4½IU(121)

|

121.44

|

4½IU

|

114.30

|

119.06

|

|

DDZ4½EU(133)

|

133.35

|

4½EU

|

114.30

|

127.00

|

|

DDZ5IEU(133)

|

133.35

|

5IEU

|

127.00

|

130.18

|

|

DDZ5½IEU(148)

|

147.64

|

5½IEU

|

139.70

|

144.46

|

|

DDZ6⅝IEU(179)

|

178.49

|

6⅝IEU

|

168.28

|

176.21

|

Note:1.IU means internal upset,EU means external upset,IEU means internal and external upset.

2.Any elevator can be selected from the max load series listed in above chart.

3.DDZ (T) center latch bottleneck drill pipe elevators for top drive are conventional center door elevators for handling taper shoulder drill pipes in oil and gas drilling operation,are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 2250kN to 4500kN, and cover pipe sizes from 3½EU to 6⅝IEU; OD, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

|

Specification

|

Bore Diameter

(mm)

|

Applicable for drill pipes

|

Rating load

TonŁškNŁ©

|

|

SpecŁšinŁ©

|

SizeŁšmmŁ©

|

Bottleneck O.D.ŁšmmŁ©

|

|

DDZ(T)3½EU(101)

|

100.81

|

3½EU

|

88.90

|

98.43

|

250t(2250kN)

350t(3150kN)

500t(4500kN)

|

|

DDZ(T)4IU(109)

|

108.74

|

4IU

|

101.60

|

106.36

|

|

DDZ(T)4EU(121)

|

121.44

|

4EU

|

101.60

|

114.30

|

|

DDZ(T)4½IU(121)

|

121.44

|

4½IU

|

114.30

|

119.06

|

|

DDZ(T)4½EU(133)

|

133.35

|

4½EU

|

114.30

|

127.00

|

|

DDZ(T)5IEU(133)

|

133.35

|

5IEU

|

127.00

|

130.18

|

|

DDZ(T)5½IEU(148)

|

147.64

|

5½IEU

|

139.70

|

144.46

|

|

DDZ(T)6⅝IEU(179)

|

178.59

|

6⅝IEU

|

168.28

|

176.21

|

Note:1.IU means internal upset,EU means external upset,IEU means internal and external upset.

2.Any elevator can be selected from the max load series listed in above chart.

4.CD side latch drill pipe elevators or are conventional side door elevators for handling square shoulder drill pipes in oil and gas drilling operation, CD drill pipe elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 125t(1125kN) to 500t(4500kN), and cover pipe sizes from 2⅜EU to 5½IEU; OD, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

|

specification

|

bore diameter

|

model of drill pipe

|

rating load

ton/kN)

|

|

upper bore (mm)

|

lower bore (mm)

|

in

|

mm

|

|

CD 2⅜EU(63*69)

|

69

|

63

|

2⅜EU

|

60.3

|

125t(1125kN)

150t(1350kN)

200t(1800kN)

250t(2250kN)

300tŁš2700kNŁ©

350t(3150kN)

400tŁš3600kNŁ©

500t(4500kN)

|

|

CD 2⅞EU(76*86)

|

85.73(86)

|

76

|

2⅞EU

|

73.0

|

|

CD 3½EU(92*103)

|

103.19(103)

|

92

|

3½EU

|

88.9

|

|

CD 4IU(105*110)

|

109.54(110)

|

105

|

4IU

|

101.6

|

|

CD 4EU(105*118)

|

117.48(118)

|

105

|

4EU

|

101.6

|

|

CD 4½IU(118*122)

|

122.24(122)

|

118

|

4½IU

|

114.3

|

|

CD 4½EU(118*131)

|

131

|

118

|

4½EU

|

114.3

|

|

CD 5IEU(131*135)

|

134.94(135)

|

131

|

5IEU

|

127.0

|

|

CD 5½IEU(144*149)

|

149.23(149)

|

144

|

5½

|

139.7

|

note:IUmeans internal upset;EUmeans external upset;IEU means internal and external upset.

The size of upper and lower bores of drill pipe elevator can be the same.

5.CDZ side latch bottleneck drill pipe elevators are conventional tools to handle the drill pipes in oil and gas drilling operation.

Side latch bottleneck drill pipe elevators Maximum load: 100t (900kN) ~ 500t (4500kN).

Applies to drill pipes diameter: 2⅜EU ~ 5½IEU.

Model of drill pipe:IUmeans internal upset,EU means external upset,IEUmeans internal & external upset.

|

Specification

|

Bore Dia(in)

|

Joint code and type

|

Bore Dia.

(mm)

|

Rated load

t(kN)

|

Elevators tag

|

|

CDZ 2⅜EU/100(68/900)

|

2⅜EU

|

NC26(2⅜ IF)

|

68

|

100t

(100kN)

|

CDZ 2⅜EU/100 SR1 API 8C PSL1

|

|

CDZ 2⅞EU/100(83/900)

|

2⅞EU

|

NC31(2⅞ IF)

|

83

|

CDZ 2⅞EU/100 SR1 API 8C PSL1

|

|

CDZ 3½EU/100(101/900)

|

3½EU

|

NC38(3½ IF)

|

101

|

CDZ 3½EU/100 SR1 API 8C PSL1

|

|

CDZ 4½IEU/100(121/900)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/100 SR1 API 8C PSL1

|

|

CDZ 5IEU/100(133/1350)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/100 SR1 API 8C PSL1

|

|

CDZ 2⅜EU/150(68/1350)

|

2⅜EU

|

NC26(2⅜ IF)

|

68

|

150t

(1350kN)

|

CDZ 2⅜EU/150 SR1 API 8C PSL1

|

|

CDZ 2⅞EU/150(83/1350)

|

2⅞EU

|

NC31(2⅞ IF)

|

83

|

CDZ 2⅞EU/150 SR1 API 8C PSL1

|

|

CDZ 3½EU/150(101/1350)

|

3½EU

|

NC38(3½ IF)

|

101

|

CDZ 3½EU/150 SR1 API 8C PSL1

|

|

CDZ 4½IEU/150(121/1350)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/150 SR1 API 8C PSL1

|

|

CDZ 5IEU/150(133/1350)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/150 SR1 API 8C PSL1

|

|

CDZ 5½IEU/150(148/1350)

|

5½IEU

|

5½ FH

|

148

|

CDZ 5½IEU/150 SR1 API 8CPSL1

|

|

CDZ 2⅜EU/200(68/1800)

|

2⅜EU

|

NC26(2⅜ IF)

|

68

|

200t

(1800kN)

|

CDZ 2⅜EU/200 SR1 API 8C PSL1

|

|

CDZ 2⅞EU/200(83/1800)

|

2⅞EU

|

NC31(2⅞ IF)

|

83

|

CDZ 2⅞EU/200 SR1 API 8C PSL1

|

|

CDZ 3½EU/200(101/1800)

|

3½EU

|

NC38(3½ IF)

|

101

|

CDZ 3½EU/200 SR1 API 8C PSL1

|

|

CDZ 4½IEU/200(121/1800)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/200 SR1 API 8C PSL1

|

|

CDZ 5IEU/200(133/1800)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/200 SR1 API 8C PSL1

|

|

CDZ 5½IEU/250(148/1800)

|

5½IEU

|

5½ FH

|

148

|

CDZ 5½IEU/200 SR1 API 8C PSL1

|

|

CDZ 2⅞EU/250(83/2250)

|

2⅞EU

|

NC31(2⅞ IF)

|

83

|

250t

(2250kN)

|

CDZ 2⅞EU/250 SR1 API 8C PSL1

|

|

CDZ 3½EU/250(101/2250)

|

3½EU

|

NC38(3½ IF)

|

101

|

CDZ 3½EU/250 SR1 API 8C PSL1

|

|

CDZ 4½IEU/250(121/2250)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/250 SR1 API 8C PSL1

|

|

CDZ 5IEU/250(133/2250)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/250 SR1 API 8C PSL1

|

|

CDZ 5½IEU/250(148/2250)

|

5½IEU

|

5½ FH

|

148

|

CDZ 5½IEU/250 SR1 API 8C PSL1

|

|

CDZ 3½EU/350(101/3150)

|

3½EU

|

NC38(3½ IF)

|

101

|

350t

(3150kN)

|

CDZ 3½EU/350 SR1 API 8C PSL1

|

|

CDZ 4½IEU/350(121/3150)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/350 SR1 API 8C PSL1

|

|

CDZ 5IEU/350(133/3150)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/350 SR1 API 8C PSL1

|

|

CDZ 5½IEU/350(148/3150)

|

5½IEU

|

5½ FH

|

148

|

CDZ 5½IEU/350 SR1 API 8C PSL1

|

|

CDZ 3½EU/500(101/4500)

|

3½EU

|

NC38(3½ IF)

|

101

|

500t

(4500kN)

|

CDZ 3½EU/500 SR1 API 8C PSL1

|

|

CDZ 4½IEU/500(121/4500)

|

4½IEU

|

NC46(4½ IF)

|

121

|

CDZ 4½IEU/500 SR1 API 8C PSL1

|

|

CDZ 5IEU/500(133/4500)

|

5IEU

|

5½ FH

|

133

|

CDZ 5IEU/500 SR1 API 8C PSL1

|

|

CDZ 5½IEU/500(148/4500)

|

5½IEU

|

5½ FH

|

148

|

CDZ 5½IEU/500 SR1 API 8C PSL1

|

note:IU means internal upset,EU means external upset,IEU means internal & external upset.

Casing elevator

1.DD center latch Casing elevators are conventional center door elevators for handling square shoulder casing in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 150t(1350kN) to 250t(2250kN), and cover pipe sizes from 4 1/2in to 14in, link ears conform to API elevator links, center Door drill pipe elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity. 1.DD center latch Casing elevators are conventional center door elevators for handling square shoulder casing in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 150t(1350kN) to 250t(2250kN), and cover pipe sizes from 4 1/2in to 14in, link ears conform to API elevator links, center Door drill pipe elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

2.SLX type side latch casing elevators are conventional side door elevators for handling square shoulder casing pipes in oil and gas deilling operation, side latch Casing elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 1350kN to 3150kN, and cover pipe sizes from 4 1/2in to 20in; OD, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of casing and rated working capacity.

3.CD side latch casing elevators are conventional side door elevators for handling square shoulder casing pipes in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 100t(900kN) to 750t(6750kN), and cover pipe sizes from 4 1/2in to 36in;link ears conform to API elevator links, Side Door Casing elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

Drill collar elevator

1.CD(A) side latch drill collar elevators are conventional side door elevators for handling square shoulder drill pipes in oil and gas deilling operation, side latch drill collar elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang 1350kN, and cover pipe sizes from 2½in to 11in; OD, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of collar and rated working capacity. 1.CD(A) side latch drill collar elevators are conventional side door elevators for handling square shoulder drill pipes in oil and gas deilling operation, side latch drill collar elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang 1350kN, and cover pipe sizes from 2½in to 11in; OD, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of collar and rated working capacity.

2.DD center latch drill collar elevators are conventional center door elevators for handling square shoulder drill pipes in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from1350kN to 2250kN, and cover pipe sizes from 2½in to 11in OD, IU, EU, or IEU. link ears conform to API elevator links, center Door drill pipe elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

3.CD side latch drill Collar elevators are conventional side door elevators for handling square shoulder drill pipes in oil and gas drilling operation, side latch drill Collar elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 900kN to 1800kN, and cover pipe sizes from 3in to 11¼in; link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

Tubing elevator

1.DD(AA) Collar type Center Latch tubing Elevators are convention square center latch elevators to handle tubing pipes in oil and gas drilling operation.The elevators can handle taper shoulder tubing from 1.9in to 4 1/2EU O.D.EU The rating loads are as follows: 65t(585kN),100t(900kN), 125t(1125kN),150t(1350kN) and etc. every technical parameters and properties of the equipment offered to customers are in accordance with the specifications of API Spec 8C and SY/T 5035 Elevator link, Elevator and Manual Tong. 1.DD(AA) Collar type Center Latch tubing Elevators are convention square center latch elevators to handle tubing pipes in oil and gas drilling operation.The elevators can handle taper shoulder tubing from 1.9in to 4 1/2EU O.D.EU The rating loads are as follows: 65t(585kN),100t(900kN), 125t(1125kN),150t(1350kN) and etc. every technical parameters and properties of the equipment offered to customers are in accordance with the specifications of API Spec 8C and SY/T 5035 Elevator link, Elevator and Manual Tong.

2.DD(TA) Center Latch Tubing Elevators are convention square center latch elevators to handle pipes in oil and gas drilling operation.The elevators can handle taper shoulder tubing from 1.9in to 4 1/2EU O.D.EU.The rating loads are as follows: 65t(585kN),100t(900kN), 125t(1125kN),150t(1350kN) and etc.every technical parameters and properties of the equipment offered to customers are in accordance with the specifications of API Spec 8C and SY/T 5035 Elevator link, Elevator and Manual Tong.

3.BD Locking ring type tubing elevator are conventional side latch elevators for handling square shoulder drill pipes in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 40t(360N) to 75t(585kN), and cover pipe sizes from 1.9"in to 4 1/2in; OD, IEU. link ears conform to API elevator links, BD Locking ring type tubing elevator bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

4.CD side latch tubing elevators are conventional side door elevators for handling square shoulder tubing pipes in oil and gas drilling operation, the elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 50t(360kN) to 125t(1125kN), and cover pipe sizes from 1.9in to 4 1/2EU;link ears conform to API elevator links, Side Door tubing elevators bear API monogram as per API requirements, and marked with size of drill pipe and rated working capacity.

5.CD(A) side latch Tubing elevators are conventional side door elevators for handling square shoulder tubing pipes in oil and gas deilling operation, side latch Tubing elevators are cast from high quality alloy steel, heat-treated, and NDT tested. the rated loads rang from 360kN to 1350kN, and cover pipe sizes from 1.9 in to 4 1/2in; O.D, IU, EU, or IEU. link ears conform to API elevator links, the elevators bear API monogram as per API requirements, and marked with size of tubing and rated working capacity.

Sucker Rod Elevator

1. Description 1. Description

ąĆCDQ(S) Sucker Rod Elevators series are important apparatus to handle the descending and ascending of the drill pipes in the operation of well-repairing in oilfield.

ąÆWith reasonable design,easy operation,safety and reliability and qualified materials, T-Brand CDQ(S) Sucker Rod Elevators series are manufactured by both advanced technology and special intensity heat treatment. They are verified with super structural and wear-resisting nature by strict strength test and NDT. They can handle sucker rods of ⅝in-1 1/4in diameter used in the operation of descending and ascending.

ąÇAll the technical parameter and property of the elevators completely conform to the requirements of SY5235 and API Spec 8C.

2. Specifications for CDQ(S) Sucker Rod Elevators

Chart for specifications of CDQ(S) Sucker Rod Elevators:

|

Specification

|

Bore Diameter(mm)

|

The application of Sucker Rod Elevator specification

|

Rating Load

t(kN)

|

|

mm

|

in

|

|

CDQ(S)23/135

|

23

|

16-19

|

⅝-¾

|

15t

(135kN)

|

|

CDQ(S)26/135

|

26

|

19-22

|

¾-⅞

|

|

CDQ(S)30/135

|

30

|

22-25

|

1

|

|

CDQ(S)33/135

|

33

|

25-28

|

1⅛

|

|

CDQ(S)23/225

|

23

|

16-19

|

⅝-¾

|

25t

(225kN)

|

|

CDQ(S)26/225

|

26

|

19-22

|

¾-⅞

|

|

CDQ(S)30/225

|

30

|

22-25

|

1

|

|

CDQ(S)33/225

|

33

|

25-28

|

1⅛

|

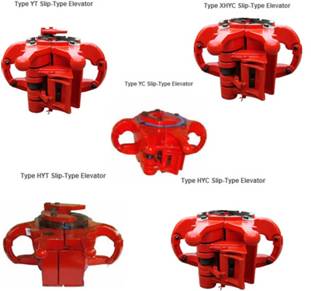

Slip type elevator

1. Type YT Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel. 1. Type YT Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel.

Application of pipe column diameter:2 3/8in-2 7/8in.

Rated load:75t(675kN).

Executive standard:API Spec 8A,API Spec 8CSY/T5035,SY/T5049.

2. Type HYT Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel.

Application of pipe column diameter:3 1/2in-7in.

Rated load:150t(1350kN).

Executive standard:API Spec 8A,API Spec 8C,SY/T5035,SY/T5049.

3. Type YC Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel.

Application of pipe column diameter:3 1/2in-7in.

Rated load:75t(675kN).

Executive standard:API Spec 8A,API Spec 8C,SY/T5035,SY/T5049.

4. Type HYC Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel.

Application of pipe column diameter:3 1/2in-7 5/8in.

Rated load:150t(1350kN).

Executive standard:API Spec 8A,API Spec 8C,SY/T5035,SY/T5049.

5. Type XHYC Slip-Type Elevators are for handling drill pipe,tubing and casing in oil and gas drilling or workover operation to prevent bottlenecking and gauge damage, all the slip type elevators except dies are cast from high quality alloy steel, the dies are forged from high quality alloy steel.

Application of pipe column diameter:3 1/2in-7 5/8in.

Rated load:350t(3150kN).

Executive standard:API Spec 8A,API Spec 8C,SY/T5035,SY/T5049.

Single joint elevator

1. Description 1. Description

ąĆDDF type center latch single joint elevators are conventional tools for handling a single joint of casing or tubing in oil and gas drilling operation, the rated load are 5t(45kN) and 10t(90kN), and cover pipe sizes from 4½in to 20in OD. SJ single joint elevators are designed and manufactured in accordance with API Spec 8C.

2. Specifications for center latch single joint elevators

Chart for specifications of center latch single joint elevators:

|

specification

|

pipe O.D. (in)

|

pipe O.D. (mm)

|

Rated Load kN(t)

|

|

DDF117/45(4½/5)

|

4½

|

116.69

|

45(5)

|

|

DDF142/45(5½/5)

|

5½

|

142.88

|

|

DDF171/45(6⅝/5)

|

6

|

171.45

|

|

DDF181/45(7/5)

|

7

|

180.98

|

|

DDF197/45(7⅝/5)

|

7⅝

|

197.64

|

|

DDF223/45(8⅝/5)

|

8⅝

|

223.04

|

|

DDF248/45(9⅝/5)

|

9⅝

|

248.44

|

|

DDF277/45(10¾/5)

|

10¾

|

277.83

|

|

DDF331/45(12⅞/5)

|

12⅞

|

331.80

|

|

DDF344/45(13⅜/5)

|

13⅜

|

344.50

|

|

DDF350/45(13⅝/5)

|

13⅝

|

350.85

|

|

DDF360/45(14/5)

|

14

|

360.76

|

|

DDF411/45(16/5)

|

16

|

411.40

|

|

DDF479/90(18⅝/5)

|

18⅝

|

479.43

|

90(10)

|

| |

|

|

SE Elevator/Spider SE Elevator/Spider

Slip Type Elevators/Spiders are mechanized tools with air operating. They can handle casings up to5.1/2inch. They are easy to operate and dependable enough. Also they can reduce workload. They are designed and manufactured according to API Spec 8C.

|

Specification

|

SizeŁšinŁ©

|

Max.load

|

Working pressure

|

|

Slip body

|

Size

|

|

SE150

|

3.1/2

|

2.3/8

|

150tons

(1334kN)

|

0.6Ą«0.8mpa

|

|

2.7/8

|

|

3.1/2

|

|

5.1/2

|

4

|

|

4.1/2

|

|

5

|

|

5.1/2

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/20 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|