|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

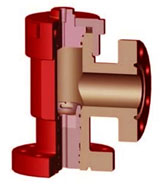

| Choke Valve |

|

MANUAL ADJUSTABLE CHOKE VALVE (JLK)  - No elastomer seals used in valves - No elastomer seals used in valves

- Shut-off pipelines at emergency by utilization of holed-disc choke valves.

- With pressure buffer tubes

- Sufficient thru-bore up to 4 1/16 inch.

- Working pressure up to 20,000 PSI

- Solid manifold available for offshore

Features:

- Convertibility: Positive Chokes can be converted readily to adjustable chokes by replacement of interchangeable bonnet and trims.

- Hardened stem and seat to withstand most erosive effects of highly abrasive materials

- Metal to metal seals between body and bonnet.

- Quick change connections for easy field maintenance

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Bushing

|

1

|

Teflon

|

|

2

|

Valve body

|

1

|

35CrMo

|

|

3

|

Valve bonnet bolt

|

8

|

35CrMo

|

|

4

|

O-ring

|

2

|

NBR

|

|

5

|

Seat bushing

|

1

|

35CrMo

|

|

6

|

Valve seat barrel

|

1

|

YG8

|

|

7

|

Stem adaptor

|

1

|

35CrMo

|

|

8

|

Valve core

|

1

|

YG8

|

|

9

|

O-ring

|

2

|

NBR

|

|

10

|

Packing box

|

1

|

35CrMo

|

|

11

|

O-ring

|

2

|

NBR

|

|

12

|

Valve bonnet

|

1

|

35CrMo

|

|

13

|

Packing gland

|

1

|

35CrMo

|

|

14

|

Valve bonnet nut

|

8

|

35CrMo

|

|

15

|

Valve stem

|

1

|

2Cr13

|

|

16

|

Screw housing

|

1

|

40Cr

|

|

17

|

Saddle key

|

1

|

45

|

|

18

|

Valve stem nut

|

1

|

ZcuA19-4

|

|

19

|

Hand wheel

|

1

|

QT400-17

|

|

20

|

Indicator ring

|

1

|

2Cr13

|

|

21

|

Stem protector

|

1

|

Q235

|

|

22

|

Bearing bonnet

|

1

|

40Cr

|

|

23

|

Bearing

|

2

|

ĄĄ

|

|

24

|

Flat key

|

1

|

ĄĄ

|

|

25

|

Grease cup

|

1

|

ĄĄ

|

|

26

|

Packing ring

|

2

|

2Cr13

|

|

27

|

Packing

|

5

|

FKM

|

HYDRAULIC ADJUSTABLE CHOKE VALVE (JLKY)

- Size 2 1/16" thru 4 1/16" - Size 2 1/16" thru 4 1/16"

- Working Pressure: 3,000 thru 15,000 PSI

- Temp: - 60ĄăC to 121ĄăC (K, U)

- Trim: AA thru FF

- PSL: 3 thru 4

- PR: 1 thru 2

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Valve Body

|

1

|

35CrMo

|

|

2

|

Bushing

|

1

|

FKM

|

|

3

|

Valve seat bolt

|

1

|

35CrMo

|

|

4

|

O-ring

|

1

|

Rubber

|

|

5

|

Valve seat

|

1

|

YG8

|

|

6

|

Fastening cap

|

1

|

45

|

|

7

|

Valve core

|

1

|

YG8

|

|

8

|

Lower fluid guide bushing

|

1

|

2Cr13

|

|

9

|

Upper fluid guide bushing

|

1

|

2Cr13

|

|

10

|

Valve stem

|

1

|

2Cr13

|

|

11

|

O-ring

|

1

|

Rubber

|

|

12

|

O-ring

|

2

|

Rubber

|

|

13

|

Valve bonnet

|

1

|

35CrMo

|

|

14

|

Oil cylinder

|

1

|

35CrMo

|

|

15

|

Oil cylinder joint

|

2

|

35CrMo

|

|

16

|

O-ring

|

2

|

rubber

|

|

17

|

O-ring

|

2

|

rubber

|

|

18

|

O-ring

|

2

|

rubber

|

|

19

|

piston

|

1

|

45

|

|

20

|

Cylinder cover

|

1

|

35CrMo

|

|

21

|

clip

|

1

|

65CrMo

|

|

22

|

screw

|

4

|

35CrMo

|

|

23

|

washer

|

1

|

35CrMo

|

|

24

|

O-ring

|

2

|

rubber

|

|

25

|

Valve bonnet nut

|

8

|

40Cr

|

|

26

|

Packing gland

|

1

|

40Cr

|

|

27

|

Valve bonnet bolt

|

8

|

35CrMo

|

|

28

|

Packing ring

|

2

|

2Cr13

|

|

29

|

packing

|

5

|

FKM

|

POSITIVE CHOKE VALVE

Positive choke valve is used as flow control of wellhead and X-mas tree. All pressure-containing parts are made of alloy steel with enough tensile strength to ensure the safety and reliability at rated working pressure. Choke beans are made of hard alloys for good wear and erosion resistance. Positive choke valve is used as flow control of wellhead and X-mas tree. All pressure-containing parts are made of alloy steel with enough tensile strength to ensure the safety and reliability at rated working pressure. Choke beans are made of hard alloys for good wear and erosion resistance.

Technical parameters:

- Pressure rating: 2000~15000psi

- Operating temperature: P U

- Operating medium: oil, gas and water

- Choke bore diameter: 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16mm

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Body

|

1

|

4130

|

|

2

|

O-Ring

|

2

|

NBR

|

|

3

|

Valve Core

|

1

|

4130

|

|

4

|

Circlip

|

1

|

1566

|

|

5

|

Choke Bean

|

1

|

YG8

|

|

6

|

O-Ring

|

1

|

NBR

|

|

7

|

Cover

|

1

|

4130

|

|

8

|

Cover Nut

|

1

|

1045

|

|

9

|

Grease Fitting

|

1

|

Aaay.

|

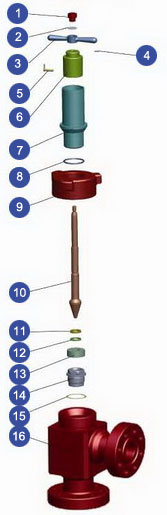

H2 CHOKE VALVE

Feature: Feature:

- Needle and Seat design provide for fully adjustable flow

- Adjustable models easily adaptable to positive configurations

- Needle and seat available in standard or super trim

- Interchangeable with Cameron H2 style adjustable choke valve

- Thumb screw secures Stem position at any setting

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Hex Bolt or Nut

|

1

|

Steel

|

|

2

|

Washer

|

1

|

5140

|

|

3

|

Handwheel

|

1

|

QT-40-18

|

|

4

|

Set Scriew

|

3

|

Rubber Steel

|

|

5

|

Thumb Screw

|

1

|

Steel

|

|

6

|

Indicator

|

1

|

F4+Flexible Graphite

|

|

7

|

Plug

|

1

|

4130

|

|

8

|

O-ring

|

1

|

NBR

|

|

9

|

Bonnet Nut

|

1

|

4130

|

|

10

|

Needle

|

1

|

4130+Ni

|

|

11

|

Ring Gasket

|

1

|

1020

|

|

12

|

Seal Ring

|

1

|

410/304

|

|

13

|

Packing

|

1

|

NBR

|

|

14

|

Seat

|

1

|

410

|

|

15

|

Ring Gasket

|

1

|

316

|

|

16

|

Valve Body

|

1

|

4130

|

ORIFACE CHOKE VALVE

Orifice choke valve is molded of two pieces of special carbon tungsten plates with excellent ability of erosion resistance, one of which rotates to alter the concentricity between the upper orifice and lower orifice of two plates so as to adjust the flow-rate of fluid or gas. Orifice choke valve is molded of two pieces of special carbon tungsten plates with excellent ability of erosion resistance, one of which rotates to alter the concentricity between the upper orifice and lower orifice of two plates so as to adjust the flow-rate of fluid or gas.

The valve is used for manifold such as drilling, fracture, mud circuit, ground high-pressure gas injection/production, it has a outstanding feature that the pressure difference between inlet and outlet, as closing, can press both of the plates fast together so as to put into effect of sealing cutting, especially in the case that the pressure suddenly rises or falls, the pre-set sign-rate of high/low pressure sensor can be helpful for automatic closing/shut so as to avoid heavy accident. It is outstanding advantage that it has long working life and ability of erosion/corrosion resistance in comparing with other choke valves.

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|