|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Pumping unit |

|

CYJ Pumping Units  Brief Introduction Brief Introduction

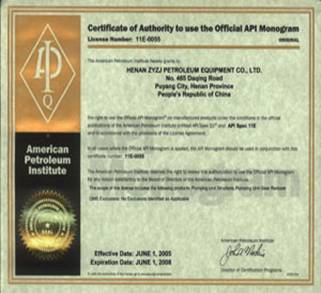

Conventional CYJ pumping units with walking beams are among the most common and most widely used power units in rod production on oil fields.Products comply with Specifications of Pumping Units (API Spec 11E), Pumping units with Walking Beams (SY/T5044) and other related standards, and have acquired the authorization to use Official API Monogram.

Technical Performance & Characteristics Technical Performance & Characteristics

1.Modular and virtual manufacturing technologies are adopted in design, so that the structure of products is optimized and components are highly standardized, generalized and seriated. ĄĄĄĄ2.Key structural elements are subject to finite element analysis to ensure stable performance and high reliability. ĄĄ

3.Reducers are driven by double-arc symmetrical split or involute herringbone wheels that are properly sealed and distinguished with low noise, smooth operation, reliable and durable service. ĄĄĄĄ

4.The entire machine features simple operation and maintenance and extended service life.

Major Technical Parameters

|

Model

|

Rated rod load kN

|

Stroke m

|

Frequency of stroke rpm

|

Rated torque of positive speed gearboxes kN.m

|

|

CYJ3-1.5-9HB

|

30

|

1.5/1.2/0.9

|

6/9/12

|

9

|

|

CYJ4-1.5-9HB

|

40

|

1.5/1.2/0.9

|

6/9/12

|

9

|

|

CYJ5-2.5-13HB

|

50

|

1.8/1.5/1.2

|

6/9/12

|

13

|

|

CYJ6-2.5-18HB

|

50

|

2.5/2.0/1.5

|

6/9/12

|

18

|

|

CYJ6-2.5-26HB

|

60

|

2.5/2.0/1.5

|

6/9/12

|

26

|

|

CYJ8-3-37HB

|

80

|

3/2.5/2.0

|

6/9/12

|

37

|

|

CYJY10-3-53HF

|

100

|

3/2.5/2.1

|

6/9/12

|

53

|

|

CYJY10-4.2-53HF

|

100

|

4.2/3.5/2.8

|

5/6/8

|

53

|

|

CYJY12-4.8-73HF

|

120

|

4.8/3.6/2.5

|

4/6/8

|

73

|

|

CYJB12-4.8-53HB

|

120

|

4.8/3.9/3.0

|

4/6/8

|

53

|

|

CYJBG12-4.8-53HB

|

120

|

4.8/4.2/3.6/3.0

|

4/6/8

|

53

|

|

CYJBG14-4.8-53HB

|

140

|

4.8/4.5/4.2/3.9/3.6/3.3

|

4/5/6

|

53

|

|

CYJY14-4.8-73HF/A

|

140

|

4.8/3.9/3.1

|

4/6/8

|

73

|

|

CYJY14-4.8-73HF/B

|

140

|

4.8/3.9/3.1

|

4/5/6

|

73

|

|

CYJY14-4.8-73HF/C

|

140

|

4.8/3.9/3.1

|

4/6/8

|

73

|

|

CYJY16-5.4-89HF

|

160

|

5.4/4.5/3.6

|

4/5/6

|

89

|

|

CYJY16-5.4-89HF/B

|

160

|

5.4/4.5/3.6

|

4/5/6

|

89

|

|

CYJ6-2.5-26HY

|

60

|

2.5/2.0/1.5

|

5/6/7

|

26

|

|

CYJ8-3-37HY

|

80

|

3/2.4/1.8

|

4/5/6

|

37

|

|

CYJY10-3-37HY

|

100

|

3/2.4/1.8

|

4/5/6

|

37

|

API C Pumping units

Brief Introduction Brief Introduction

Conventional API C pumping units with walking beams, balanced by cranks, are among the most common and most widely used power units in rod production on oil fields.Products comply with Specifications of Pumping Units (API Spec 11E) and other related standards, and have acquired the authorization to use Official API Monogram.

Technical Performance & Characteristics Technical Performance & Characteristics

1.Modular and virtual manufacturing technologies are adopted in design, so that the structure of products is optimized and components are highly standardized, generalized and seriated. ĄĄĄĄ

2.Key structural elements are subject to finite element analysis to ensure stable performance and high reliability. ĄĄĄĄ

3.Reducers are driven by double-arc symmetrical split or involute herringbone wheels that are properly sealed and distinguished with low noise, smooth operation, reliable and durable service.

4.The entire machine features simple operation and maintenance and extended service life.

Major Technical Parameters

|

Model

|

Rated polished rod load (lbs)

|

Stroke (in)

|

Rated torque of reducers (in.lbs)

|

|

C-1824D-427-240

|

42,700

|

240Ąą212Ąą196Ąą160

|

1824,000

|

|

C-1280D-365-240

|

36,500

|

240Ąą212Ąą196Ąą160

|

1280,000

|

|

C-1280D-305-240

|

30,500

|

240Ąą212Ąą196Ąą160

|

1280,000

|

|

C-912D-470-240

|

47,000

|

240Ąą212Ąą196Ąą160

|

912,000

|

|

C-912D-427-216

|

42,700

|

216Ąą185Ąą155

|

912,000

|

|

C-912D-427-192

|

42,700

|

192Ąą165Ąą138

|

912,000

|

|

C-912D-305-192

|

30,500

|

192Ąą165Ąą138

|

912,000

|

|

C-912D-365-168

|

36,500

|

168Ąą144Ąą121

|

912,000

|

|

C-912D-305-168

|

30,500

|

168Ąą144Ąą121

|

912,000

|

|

C-912D-427-144

|

42,700

|

144Ąą123Ąą102

|

912,000

|

|

C-640D-305-192

|

30,500

|

192Ąą165Ąą138

|

640,000

|

|

C-640D-305-168

|

30,500

|

168Ąą144Ąą121

|

640,000

|

|

C-640D-365-144

|

36,500

|

144Ąą123Ąą102

|

640,000

|

|

C-640D-305-144

|

30,500

|

144Ąą123Ąą102

|

640,000

|

|

C-640D-256-144

|

25,600

|

144Ąą123Ąą102

|

640,000

|

|

C-640D-305-120

|

30,500

|

120Ąą102Ąą84

|

640,000

|

|

C-456D-305-168

|

30,500

|

168Ąą144Ąą121

|

57,000

|

|

C-456D-305-144

|

30,500

|

144Ąą123Ąą102

|

40,000

|

|

C-456D-256-144

|

25,600

|

144Ąą123Ąą102

|

57,000

|

|

C-456D-365-120

|

36,500

|

120Ąą102Ąą84

|

40,000

|

|

C-456D-305-120

|

30,500

|

120Ąą102Ąą84

|

25,000

|

|

C-456D-256-120

|

25,600

|

120Ąą102Ąą84

|

25,000

|

|

C-320D-256-144

|

25,600

|

144Ąą123Ąą102

|

320,000

|

|

C-320D-256-120

|

25,600

|

120Ąą102Ąą84

|

320,000

|

|

C-320D-213-120

|

21,300

|

120Ąą102Ąą84

|

320,000

|

|

C-320D-305-100

|

30,500

|

100Ąą85Ąą70

|

320,000

|

|

C-320D-256-100

|

25,600

|

100Ąą85Ąą70

|

320,000

|

|

C-320D-213-86

|

21,300

|

86Ąą71Ąą56

|

320,000

|

|

C-228D-213-120

|

21,300

|

120Ąą102Ąą84

|

228,000

|

|

C-228D-173-100

|

17,300

|

100Ąą86Ąą72

|

228,000

|

|

C-228D-246-86

|

24,600

|

86Ąą71Ąą56

|

228,000

|

|

C-228D-213-86

|

21,300

|

86Ąą71Ąą56

|

228,000

|

|

C-228D-200-74

|

20,000

|

74Ąą64Ąą54

|

228,000

|

|

C-228D-173-74

|

17,300

|

74Ąą64Ąą54

|

228,000

|

|

C-160D-173-86

|

17,300

|

86Ąą74Ąą62

|

160,000

|

|

C-160D-200-74

|

20,000

|

74Ąą64Ąą54

|

160,000

|

|

C-160D-173-74

|

17,300

|

74Ąą64Ąą54

|

160,000

|

|

C-160D-143-74

|

14,300

|

74Ąą64Ąą54

|

160,000

|

|

C-160D-173-64

|

17,300

|

64Ąą54Ąą44

|

160,000

|

|

C-114D-119-86

|

11,900

|

86Ąą72Ąą59

|

114,000

|

|

C-114D-143-74

|

14,300

|

74Ąą62Ąą51

|

114,000

|

|

C-114D-173-64

|

17,300

|

64Ąą54Ąą44

|

114,000

|

|

C-114D-143-64

|

14,300

|

64Ąą52Ąą40

|

114,000

|

|

C-114D-133-54

|

13,300

|

54Ąą45Ąą36

|

114,000

|

|

C-80D-119-64

|

11,900

|

64Ąą53Ąą42

|

80,000

|

|

C-80D-133-54

|

13,300

|

54Ąą45Ąą36

|

80,000

|

|

C-80D-119-54

|

11,900

|

54Ąą45Ąą36

|

80,000

|

|

C-80D-133-48

|

13,300

|

48Ąą40Ąą32

|

80,000

|

|

C-80D-109-48

|

10,900

|

48Ąą37Ąą25

|

80,000

|

|

C-57D-76-54

|

7,600

|

54Ąą41Ąą28

|

57,000

|

|

C-57D-109-48

|

10,900

|

48Ąą37Ąą25

|

57,000

|

|

C-57D-95-48

|

9,500

|

48Ąą37Ąą25

|

57,000

|

|

C-57D-89-42

|

8,900

|

42Ąą33Ąą23

|

57,000

|

|

C-57D-76-42

|

7,600

|

42Ąą33Ąą23

|

57,000

|

|

C-40D-76-48

|

7,600

|

48Ąą37Ąą27

|

40,000

|

|

C-40D-89-42

|

8,900

|

42Ąą33Ąą23

|

40,000

|

|

C-40D-76-42

|

7,600

|

42Ąą33Ąą23

|

40,000

|

|

C-40D-89-36

|

8,900

|

36Ąą28Ąą20

|

40,000

|

|

C-25D-67-36

|

6,700

|

36Ąą28Ąą20

|

25,000

|

|

C-25D-56-36

|

5,600

|

36Ąą28Ąą20

|

25,000

|

|

C-25D-53-30

|

5,300

|

30Ąą20

|

25,000

|

API B Pumping Units

Brief Introduction Brief Introduction

Conventional light API B pumping units, balanced by walking beams, are among the most common and most widely used power units in rod production on oil fields.Products comply with Specifications of Pumping Units (API Spec 11E) and other related standards, and have acquired the authorization to use Official API Monogram.

Technical Performance & Characteristics Technical Performance & Characteristics

1. Compact structure, easy operation and maintenance, and extended service life. ĄĄ

2. Reducers are driven by involute or double-arc herringbone wheels and thus can operate stably and reliably. ĄĄĄĄ

3. The entire machine is very light and thus can be installed and transported conveniently. ĄĄ

4. It is applicable in shallow oil production with small stroke and light loads.

Major Technical Parameters

|

S.N.

|

Model

|

Rated polished rod load (lb)

|

Stroke (in)

|

Rated torque of reducers (in.lb)

|

|

1

|

B-80D-119-64

|

11,900

|

64Ąą54

|

80,000

|

|

2

|

B-80D-76-64

|

7,600

|

64Ąą54

|

80,000

|

|

3

|

B-80D-133-54

|

13,300

|

54Ąą41

|

80,000

|

|

4

|

B-80-119-54

|

11,900

|

54Ąą41

|

80,000

|

|

5

|

B-80D-76-54

|

7,600

|

54Ąą41

|

80,000

|

|

6

|

B-80D-133-48

|

13,300

|

48Ąą35

|

80,000

|

|

7

|

B-80D-109-48

|

10,900

|

48Ąą35

|

80,000

|

|

8

|

B-57D-109-54

|

10,900

|

54Ąą41

|

57,000

|

|

9

|

B-57D-89-54

|

8,900

|

54Ąą41

|

57,000

|

|

10

|

B-57D-76-54

|

7,600

|

54Ąą41

|

57,000

|

|

11

|

B-57D-109-48

|

10,900

|

48Ąą35

|

57,000

|

|

12

|

B-57D-95-48

|

9,500

|

48Ąą35

|

57,000

|

|

13

|

B-57D-89-48

|

8,900

|

48Ąą35

|

57,000

|

|

14

|

B-57D-89-42

|

8,900

|

42Ąą32

|

57,000

|

|

15

|

B-40D-89-48

|

8,900

|

48Ąą35

|

40,000

|

|

16

|

B-57D-76-42

|

7,600

|

42/32

|

57,000

|

|

17

|

B-40D-76-42

|

7,600

|

42Ąą29

|

40,000

|

|

18

|

B-25D-67-36

|

6,700

|

36Ąą27

|

25,000

|

|

19

|

B-25D-53-30

|

5,300

|

30/23

|

25,000

|

|

20

|

B-16D-53-30

|

5,300

|

30Ąą23

|

16,000

|

API F Pumping Units

Brief Introduction Brief Introduction

Newly developed API F pumping units without walking beams are lower, foldable and flexibly driven power units newly applied in rod production on oil fields. Products comply with Specifications of Pumping Units (API Spec 11E) and other related standards, and have acquired the authorization to use Official API Monogram.

Technical Performance & Characteristics Technical Performance & Characteristics

1. Rollers and belts are adopted to provide flexible driving, reduce impact loads and extend the service life of reducers.

2. Unique out phase cranks are adopted to achieve absolute balance and enhance energy-saving effects.

3. The reducers are driven by symmetrical split involute herringbone wheels that are properly sealed and distinguished with low noise, smooth operation, reliable and durable service.

4. The entire machine is small in mass and volume, lower, foldable and convenient in installation and transportation. 5. Products are distinguished with compact structure, easy operation and maintenance, and high performance price ratio.

Major Technical Parameters

|

S.N.

|

Model

|

Rated polished rod load (lb)

|

Stroke (in)

|

Rated torque of reducers (in.lb)

|

|

1

|

F-320D-256-120

|

25,600

|

120Ąą102Ąą84

|

320,000

|

|

2

|

F-320D-256-100

|

25,600

|

100Ąą86Ąą74

|

320,000

|

|

3

|

F-320D-246-86

|

24,600

|

86Ąą74Ąą62

|

320,000

|

|

4

|

F-228D-256-100

|

25,600

|

100Ąą86Ąą74

|

320,000

|

|

5

|

F-228D-213-86

|

21,300

|

86Ąą74Ąą62

|

228,000

|

|

6

|

F-228D-246-86

|

24,600

|

86Ąą74Ąą62

|

228,000

|

|

7

|

F-228D-246-74

|

24,600

|

74Ąą64Ąą54

|

228,000

|

|

8

|

F-160D-173-86

|

17,300

|

86Ąą74Ąą62

|

160,000

|

|

9

|

F-160D-200-74

|

20,000

|

74Ąą64Ąą54

|

160,000

|

|

10

|

F-160D-173-74

|

17,300

|

74Ąą64Ąą54

|

160,000

|

|

11

|

F-114D-173-64

|

17,300

|

64Ąą54Ąą44

|

114,000

|

|

12

|

F-114D-143-54

|

14,300

|

54Ąą44Ąą34

|

114,000

|

|

13

|

F-114D-109-54

|

10,900

|

54Ąą44Ąą34

|

114,000

|

|

14

|

F-57D-89-42

|

8,900

|

42Ąą33Ąą25

|

57,000

|

API R Pumping Units

Brief Introduction Brief Introduction

Newly developed energy-saving API R pumping units with walking beams, similar in structure to conventional ones, are among the most common and most widely used power units in rod production on oil fields. Products comply with Specifications of Pumping Units (API Spec 11E) and other related standards, and have acquired the authorization to use Official API Monogram.

Technical Performance & Characteristics Technical Performance & Characteristics

1.Modular and virtual manufacturing technologies are adopted in design, and the products are similar in structure and movement characteristics to conventional pumping units with walking beams.

2.Reducers are driven by double-arc symmetrical split or involute herringbone wheels that are properly sealed and distinguished with low noise, smooth operation, reliable and durable service.

3.Cranks are in a contrary flexure angle so as to reduce the max. torque peak of reducers, increase the polar angle, enhance dynamic performance, cut down the power of power generating machines and amplify energy saving effects.

4.The structure of products is optimized, components are highly standardized, generalized and seriated, and the products feature easy operation and maintenance as well as extended service life.

Major Technical Parameters

|

S.N.

|

Model

|

Rated polished rod load (lb)

|

Stroke (in)

|

Rated torque of reducers (in.lb)

|

|

1

|

R-912D-365-192

|

36,500

|

192Ąą159Ąą127

|

912,000

|

|

2

|

R-912D-305-192

|

30,500

|

192Ąą159Ąą127

|

912,000

|

|

3

|

R-912D-365-168

|

36,500

|

168Ąą139Ąą111

|

912,000

|

|

4

|

R-912D-305-168

|

30,500

|

168Ąą139Ąą111

|

912,000

|

|

5

|

R-640D-305-192

|

30,500

|

192Ąą159Ąą127

|

640,000

|

|

6

|

R-640D-365-168

|

36,500

|

168Ąą139Ąą111

|

640,000

|

|

7

|

R-640D-305-168

|

30,500

|

168Ąą139Ąą111

|

640,000

|

|

8

|

R-456D-305-168

|

30,500

|

168Ąą139Ąą111

|

456,000

|

|

9

|

R-456D-305-144

|

30,500

|

144Ąą119Ąą95

|

456,000

|

|

10

|

R-456D-305-120

|

30,500

|

120Ąą99Ąą80

|

456,000

|

|

11

|

R-320D-256-144

|

25,600

|

144Ąą119Ąą95

|

320,000

|

|

12

|

R-320D-256-120

|

25,600

|

120Ąą99Ąą80

|

320,000

|

|

13

|

R-320D-256-100

|

25,600

|

100Ąą83Ąą67

|

320,000

|

|

14

|

R-228D-256-100

|

25,600

|

100Ąą83Ąą67

|

228,000

|

|

15

|

R-228D-246-86

|

24,600

|

86Ąą72Ąą59

|

228,000

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/26 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|