|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Stabilizer |

|

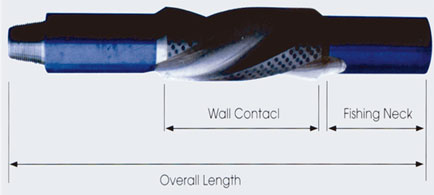

Integral Spiral/Straight Blade Drill Stabilizers

Replaceable Sleeve Drill Stabilizer Replaceable Sleeve Drill Stabilizer

Non-Rotating Drill Stabilizer

Float Valve Drill Stabilizer

Variable Diameter Drill Stabilizer

Unbalanced Spiral Blade Drill Stabilizer

Spherical Drill Stabilizer

As per API Spec 7

Integral Spiral Blade Stabilizer

ntegral Spiral Stabilizer is a one-piece tool made by AISI 4145H alloy steel and fully heat-treated to 285-341 Brinel Hardness number, and 54 Joules of minimum impact value Three spiral blades have been designed to minimize the downhole torque, to reduce damage of the hole wall, and ensure the maximum fluid circulation When drilling vertical holes, they shall be applied to reduce drift of drill bits and keep the drill bit straight downward When drilling directional holes, they can increase, decrease or stabilize the tilt of the hole, to ensure the orientation of the hole, to ensure the quality of the well, and increase the drilling speed

|

RECOMMEND SIZE OF INTEGRAL SPIRAL STABILIZER

|

|

Hole Size (in)

|

Standard DC Size

(in)

|

Wall Contact

(in)

|

Blade Width

(in)

|

Fishing Neck length

(in)

|

Blade

under-gauge (in)

|

Overall length(in)

|

Weight

|

|

String

|

Near Bit

|

(lb)

|

|

6-6 ¾

|

4 ½-4 ¾

|

16

|

2 ¼

|

28

|

~ 1/32

|

74

|

70

|

363

|

|

7 ½-8 ½

|

6 ½

|

16

|

2 ½

|

28

|

~ 1/32

|

75

|

70

|

770

|

|

9 ½-12 ¼

|

8

|

18

|

3 ½

|

30

|

~ 1/32

|

83

|

78

|

1650

|

|

14 ¾-17½

|

9 ½

|

18

|

4

|

30

|

~ 1/16

|

92

|

87

|

2204

|

|

20-26

|

9 ½

|

18

|

4

|

30

|

~ 1/16

|

100

|

95

|

3960

|

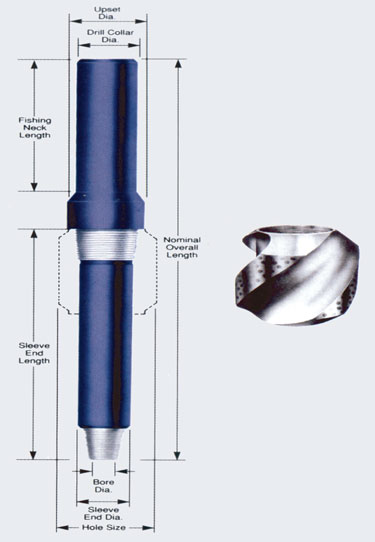

Replaceable Sleeve Stabilizer

Interchangeable Sleeve Stabilizers are made by AISI 4145H alloy steel and heat-treated to 285-341 Brinel Hardness number, and 54 Joules of impact value For each body, a series of sleeves can be fitted with it; the body is constructed in two pieces, and jointed together by the sleeve

|

RECOMMEND SIZE OF REPLACEABLE SLEEVE STABILIZER

|

|

Hole size (in)

|

Sleeve

|

DC Size (in)

|

Bore (in)

|

Upset Dia (in)

|

Center connection

|

Weight (Ib)

|

Overall length (in)

|

|

Blade width (in)

|

Length (in)

|

|

6 ¼-6 ¾

|

2

|

18

|

4 ¾

|

2

|

4 ¾

|

2 ⅞IF

|

275

|

64

|

|

7 ⅜-7 ¾

|

2

|

18

|

5 ¾

|

2 ¼

|

5 ¾

|

3 ½IF

|

396

|

66

|

|

8 ½-8 ¾

|

2 ⅜

|

18

|

6 ½

|

2 13/16

|

6 ¾

|

4IF

|

550

|

68

|

|

9 ½-11

|

2 ¾

|

18

|

7 ¼

|

2 13/16

|

7 ½

|

4 ½IF

|

726

|

68

|

|

12 ¼-17 ½

|

3 ⅛

|

24

|

9 ½

|

3

|

9 ½

|

7 ⅝ Reg

|

1210

|

81

|

|

17 ½-20

|

4

|

33

|

11 ¼

|

3

|

11 ¼

|

8 ⅝ Reg

|

1782

|

90

|

|

22-26

|

4

|

33

|

9 ½

|

3

|

9 ¼

|

7 ⅝ Reg

|

1353

|

90

|

Sleeve Stabilizer

|

Hole size (in)

|

DC Size (in)

|

Upset

Diameter (in)

|

Bottom Neck

Dia (in)

|

Overall

length (in)

|

Fishing neck length (in)

|

Weight (Ib)

|

Sleeve

length (in)

|

|

String

|

Near-Bit

|

|

6 ¼-7 ½

|

4 ¾-5

|

5 ¾

|

4 ¾

|

65

|

27

|

22

|

275

|

14

|

|

8 ½-9 ⅞

|

6 ¼-7 ¼

|

7 ½

|

6 ½

|

65

|

27

|

22

|

572

|

14

|

|

12 ¼"-17 ½

|

8 ½-9

|

9 ⅞

|

8 ½

|

66

|

27

|

22

|

1012

|

18

|

|

14 ¾-20

|

9 ½-10

|

11

|

9 ⅝

|

66

|

27

|

22

|

1210

|

22

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|