|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

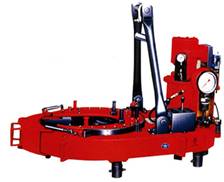

| Power tong |

|

ZQ series drill pipe power tong   The drill pipe power tong is an ideal oil drilling wellhead tools, widely used in marine, land drilling and workover operations on unloading column threaded operations. Use of this clamp can play safety, effort to improve the ergonomics of the role. The series clamp, open type, be free to disengage the column, the mobile; set torque clamp and spinner clamp at one shackle on alternative catwork, tongs and spin rope. The tongs are in line with norms SY/T5074 standards and API Spec 7K. The drill pipe power tong is an ideal oil drilling wellhead tools, widely used in marine, land drilling and workover operations on unloading column threaded operations. Use of this clamp can play safety, effort to improve the ergonomics of the role. The series clamp, open type, be free to disengage the column, the mobile; set torque clamp and spinner clamp at one shackle on alternative catwork, tongs and spin rope. The tongs are in line with norms SY/T5074 standards and API Spec 7K.

|

Model

|

ZQ127-25

|

ZQ162-50

|

ZQ203-100

|

ZQ203-125

|

|

Size range

|

Drill pipe

|

mm

|

65-127

|

85-162

|

127-203

|

127-203

|

|

in

|

23/8šĄ«31/2š

|

23/8šĄ«5š

|

31/2šĄ«8š

|

31/2šĄ«8š

|

|

Casing

|

mm

|

65-127

|

114.3Ą«153.7

|

|

|

|

in

|

23/8šĄ«31/2š

|

41/2šĄ«51/2š

|

|

|

|

Oil pipe

|

mm

|

65-127

|

138-156

|

|

|

|

in

|

23/8šĄ«31/2š

|

31/2šĄ«41/2š

|

|

|

|

Max.torque

|

kN.m

|

25

|

50

|

100

|

125

|

|

ft.lbf

|

18440

|

36880

|

73750

|

92200

|

|

Speed(High gear)

|

rpm

|

65

|

60

|

40

|

40

|

|

Speed(Low gear)

|

rpm

|

10.5

|

4.1

|

2.7

|

2.7

|

|

Air pressure

|

MPa

|

0.5šC0.9

|

|

psi

|

72šC130

|

|

Pressure rating

|

MPa

|

12

|

14

|

16.6

|

20.7

|

|

psi

|

1740

|

2030

|

2400

|

3000

|

|

Flow rating

|

L/min

|

120

|

120

|

114

|

114

|

|

gpm

|

31.7

|

31.7

|

30

|

30

|

|

Shifting distance

|

mm

|

1000

|

1000

|

1500

|

1500

|

|

in

|

39.4

|

39.4

|

59

|

59

|

|

Size

|

mm

|

1110ĄÁ735ĄÁ

815

|

1570ĄÁ800ĄÁ1190

|

1760ĄÁ1000ĄÁ1360

|

1760ĄÁ1080ĄÁ1360

|

|

in

|

44ĄÁ31ĄÁ32

|

62ĄÁ31ĄÁ47

|

69ĄÁ39ĄÁ53

|

69ĄÁ40.5ĄÁ53

|

|

Weight

|

kg

|

620

|

1500

|

2400

|

2650

|

|

lb

|

1360

|

3310

|

5290

|

5840

|

TQ Series of Casing Power Tongs TQ Series of Casing Power Tongs

TQ series of Casing Tongs are widely used for making up or breaking out pipes or casings in diameters of 4-1/2~ 13-3/8 inch. The tong heads are designed open type and can freely clamp and escape from the casing. Casing Tongs are safe, realiable and easy to handle with high mobility. They are designed and manfactured according to API Spec 7K.

Technical SpecificationsŁș

|

Model

|

TQ178-16

|

TQ340-20A

|

TQ340-35

|

TQ178-16A

|

TQ340-35A

|

TQ340-50

|

|

Size of range

|

mm

|

101.6~178

|

101.6~340

|

139.7~340

|

101.6~178

|

101.6~340

|

139.7~340

|

|

in

|

4~7

|

4~13⅜

|

5½~13⅜

|

4~7

|

4~13⅜

|

5½~13⅜

|

|

Hydraulic systemmax.pressure

|

Mpa

|

18

|

16

|

18

|

18

|

18

|

17.2

|

|

Psi

|

2610

|

2320

|

2610

|

2610

|

2610

|

2494

|

|

Hydraulic systemRated flow

|

L/min

|

114

|

114

|

114

|

114

|

114

|

120

|

|

gpm

|

30.1

|

30.1

|

30.1

|

30.1

|

30.1

|

31.7

|

|

max.torque

|

higear

|

kN.m

|

2.4~3

|

3.7

|

2.5~3

|

2.4~3

|

4.0~5.0

|

4

|

|

ft.lbf

|

1770~2200

|

2730

|

1844~2200

|

1770~2200

|

2950~3680

|

2950

|

|

midgear

|

kN.m

|

_____

|

_____

|

6.0~7.5

|

____

|

____

|

11

|

|

ft.lbf

|

4420~5530

|

8103

|

|

lowgear

|

kN.m

|

16

|

20

|

35

|

15~18

|

27~30

|

50

|

|

ft.lbf

|

11800

|

14750

|

25800

|

11060~13280

|

19900~22120

|

36851

|

|

RPM

|

higear

|

rpm

|

54~93

|

50~80

|

60~86

|

54~79

|

80~100

|

72.8

|

|

midgear

|

rpm

|

___

|

21-30

|

___

|

27.4

|

___

|

___

|

|

lowgera

|

rpm

|

9~13.1

|

6~14

|

2.6~5.3

|

8.5~12

|

12~16

|

5.4

|

|

Overall dimensions

|

mm

|

1540ĄÁ760ĄÁ740

|

1540ĄÁ850ĄÁ670

|

1520ĄÁ900ĄÁ860

|

1500ĄÁ760ĄÁ680

|

1560ĄÁ900ĄÁ850

|

1540ĄÁ892ĄÁ908

|

|

in

|

61ĄÁ30ĄÁ29

|

60ĄÁ34ĄÁ26

|

61ĄÁ36ĄÁ34

|

59ĄÁ30ĄÁ27

|

61ĄÁ35ĄÁ33.5

|

60ĄÁ35ĄÁ33

|

|

weight

|

kg

|

580

|

560

|

780

|

570

|

780

|

880

|

|

lb

|

1280

|

1234

|

1720

|

1250

|

1720

|

1940

|

TB 365-35Y Casing Back up Tong TB 365-35Y Casing Back up Tong

Product Explanation:

TB casing back-up tong is a patented product, used to perform casing operation by combined with casing power tong and can ensure connection quality and eliminate deformation of main tong under large torque. The back-up tong features safety, reliability, labor-saving, and high efficiency. There are two control style: pneumatic and hydraulic. The back-up tong is supplied with a torque sensor to measure precisely connection torque. The tong is designed and manufactured according to Industrial standard SY/T5074 and API Spec 7K Ą°Specification for Drilling EquipmentĄ±.

Product types and specifications of casing back up tong:

|

Model

|

TB194--16

|

TB365-35

|

TBH178-16S

|

TB365-35Y

|

|

Size range

|

mm

|

120.6~194

|

127~365

|

140~178

|

127~365

|

|

in

|

4~7coupling

|

41/2~133/8coupling

|

51/2~7

|

41/2~133/8coupling

|

|

Air pressure

|

MPa

|

0.5~0.9

|

0.5~0.9

|

0.5~0.9

|

ĄȘ

|

|

psi

|

72~130

|

72~130

|

72~130

|

|

Hydraulic pressure rating

|

MPa

|

ĄȘ

|

ĄȘ

|

ĄȘ

|

18

|

|

psi

|

2610

|

|

Max.bearing torque

|

kN.m

|

16

|

35

|

16

|

35

|

|

ft.lbf

|

11800

|

25810

|

11800

|

25810

|

|

Size

|

mm

|

1310ĄÁ780ĄÁ390

|

1510ĄÁ945ĄÁ405

|

1080ĄÁ1080ĄÁ350

|

1350ĄÁ950ĄÁ350

|

|

in

|

51.6ĄÁ30.7ĄÁ15.4

|

59.4ĄÁ37.2ĄÁ16

|

42.5ĄÁ42.5ĄÁ13.8

|

53.1ĄÁ37.4ĄÁ13.8

|

|

Weight

|

kg

|

360

|

480

|

1320

|

520

|

|

lb

|

790

|

1060

|

2910

|

1140

|

XYQ series of oil pipe power tongs XYQ series of oil pipe power tongs

The XYQ oil pipe power tong is used for quick make up y break out in well service operations. The tong is equipped with hydraulic back up tong and use inner curved cam to clamp. . The products are designed and manufactured strictly according to API 7K Spec Standard.

Technical Specifications

|

Model

|

XYQ3B/3C

|

XYQ6B

|

XYQ12

|

|

Pipe size of master tong

|

mm

|

§¶60-89

|

§¶73-114

|

§¶60-140

|

|

in

|

2⅜"-3½"

|

2⅞"-4½"

|

2⅜"-5½"

|

|

Pipe size of backup tong

|

mm

|

§¶60-114

|

§¶89-141.5

|

§¶73-156

|

|

in

|

2⅜"-4½"

|

3½"-5⅛"

|

2⅞"-6⅛"

|

|

Higear rated torque

|

kN.m

|

1.1

|

1.5

|

2.6

|

|

lbf.ft

|

811

|

1106

|

1918

|

|

Lowgear rated torque

|

kN.m

|

3

|

6

|

13

|

|

lbf.ft

|

2213

|

4425

|

9588

|

|

Higear rated speed

|

R/min

|

100

|

85

|

68

|

|

Lowgear rated speed

|

R/min

|

30

|

20

|

13

|

|

Rated operation pressure

|

MPa

|

10

|

11

|

12

|

|

psi

|

1450

|

1595

|

1740

|

|

Maz.flow

|

L/min

|

80

|

100

|

120

|

|

gpm

|

21

|

26

|

32

|

|

Dimension

|

mm

|

650ĄÁ430ĄÁ550

|

750ĄÁ500ĄÁ600

|

1042ĄÁ582ĄÁ839

|

|

in

|

25.6"ĄÁ16.9"ĄÁ21.7"

|

29.5"ĄÁ19.7"ĄÁ23.6"

|

41.0"ĄÁ22.9"ĄÁ33.0"

|

|

Weight(including backup tong)

|

kg

|

158

|

220

|

471

|

|

lb

|

248

|

485

|

1038

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/20 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|