|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| COMPLETION TOOLS |

|

downhole tools are designed to perform in demanding high-temperature and high-pressure (HTHP) applications in all climates and geographical locations. With resources like our own rubber shop and indoor test well, we offer unparalleled capabilities to develop and optimize tools to your specific requirements. Our API 11D1 certified packers, bridge plugs, cement retainers, flow control downhole tools, coiled tubing downhole tools and all related accessories help our customers to achieve their success in downhole operations.

downhole tools are offered in various material configurations for a variety of well conditions. The following alloys and groups of alloys are the most common materials used for the construction of packers and related equipment:

Ąö Standard, non-corrosive service: Low alloy steels (e.g. 4140 or Chinese 42CrMo) with mechanical properties compatible with API P1 10 tubulars.

Ąö Non-corrosive service containing H2S: Low alloy steels (e.g. 4140 or Chinese 42CrMo) with mechanical properties compatible with API L80 tubulars.

Ąö Corrosive CO2 service with little or no H2S: Martensitic and PH stainless steels (e.g. 9Cr, 13Cr, 17-4PH) with mechanical properties that vary from 80 ksi to 110 ksi minimum yield strength. The selection of the specific corrosion resistant alloy depends on the environment (pH, chlorides, temperature, H2S, etc.) and strength requirements.

Ąö Severely corrosive CO2 and H2S: Nickel alloys such as 718 at strength level of 110 ksi minimum yield strength and higher.

For equipment required to perform a temporary function and then allowing quick removal by drilling or milling, an additional group of materials are used:

Ąö Cast iron

Ąö Reinforced polymer based composites

|

Model

|

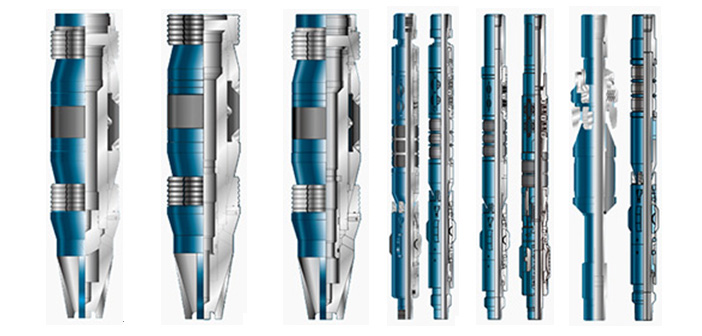

STWB Bridge Plug

|

SWRB Bridge Plug

|

SRWB Bridge Plug

|

SCP Composite Bridge Plug

|

Big Bore Bridge Plug

|

Dissolvable Bridge Plug

|

|

Size

|

2 3/8Ą±-20Ą±

|

1 1/2Ą±-5 1/2Ą±

|

5 1/2Ą±-7Ą±

|

4Ą±-7Ą±

|

5Ą±-5 1/2Ą±

|

5Ą±-5 1/2Ą±

|

|

Temperature

|

204ĄăC (400ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

177ĄăC (350ĄăF)

204ĄăC (400ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

148ĄăC (300ĄăF)

|

|

Pressure

|

70 MPa (10,000 psi)

|

52 MPa (7,500 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

|

Setting

|

Wireline/Hydraulic

|

Wireline/Hydraulic

|

Wireline/Hydraulic

|

Wireline/Hydraulic

|

Wireline/Hydraulic

|

Wireline/Hydraulic

|

|

Application

|

Isolate The Lower Zone

|

Plugging Tubing/Snubbing

|

Testing, Fracturing, Acidizing, Production, Workover

|

|

Model

|

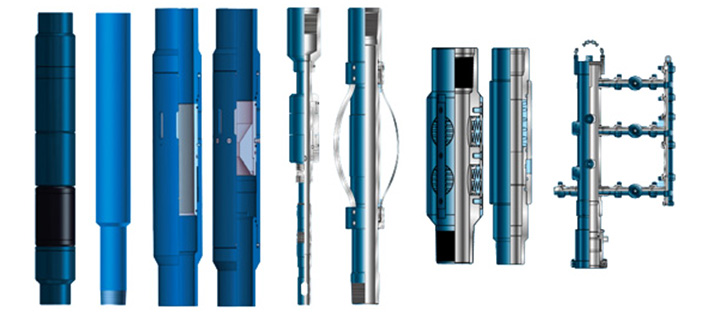

STMB Cement Retainer

|

STWR Cement Retainer

|

STMR Cement Retainer

|

SMC/SMJ Packer

|

RS-1/SRT Packer

|

STAD-1/SME Packer

|

|

Size

|

4 1/2Ą±-16Ą±

|

4 1/2Ą±-16Ą±

|

4 1/2Ą±-16Ą±

|

4 1/2Ą±-20Ą±

|

4 1/2Ą±-9 5/8Ą±

|

4 1/2Ą±-13 3/8Ą±

|

|

Temperature

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

148ĄăC (300ĄăF) 177ĄăC (350ĄăF)

|

|

Pressure

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

52 MPa (7,500 psi)

|

|

Setting

|

Mechanical

|

Wireline/Hydraulic

|

Mechanical

|

Mechanical

|

Mechanical

|

Mechanical

|

|

Application

|

Isolate The Lower Zone

|

Cementing Operation

|

Cementing Operation

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

|

Model

|

SQS Packer

|

SH-2/SHF Packer

|

SHC/SHP/SHB Packer

|

SPP-R Packer

|

SMR/SMA Packer

|

SPP-C Packer

|

|

Size

|

5Ą±-7 5/8Ą±

|

4 1/2Ą±-9 5/8Ą±

|

5 1/2Ą±-9 5/8Ą±

|

3 1/2Ą±-9 5/8Ą±

|

4 1/2Ą±-9 5/8Ą±

|

4 1/2Ą±-9 5/8Ą±

|

|

Temperature

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

148ĄăC (300ĄăF) 177ĄăC (350ĄăF)

|

204ĄăC (400ĄăF)

|

148ĄăC (300ĄăF) 177ĄăC (350ĄăF)

|

|

Pressure

|

70 MPa (10,000 psi)

|

52 MPa (7,500 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

|

Setting

|

Hydraulic

|

Hydraulic

|

Hydraulic

|

Wireline/Hydraulic

|

Mechanical

|

Wireline/Hydraulic

|

|

Application

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Production, Injection

|

Production, Injection

|

Production, Injection

|

|

Model

|

Wireline Setting Tool

|

Hydraulic Setting Tool

|

Mechanical Setting Tool

|

Tubing Anchor

|

Tubing Plug

|

|

Size

|

1 11/16Ą±-3 7/8Ą±

|

1 11/16Ą±-3 7/8Ą±

|

4 1/2Ą±-16Ą±

|

5Ą±-7 5/8Ą±

|

2 7/8Ą±-4 1/2Ą±

|

|

Temperature

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

204ĄăC (400ĄăF)

|

|

Pressure

|

70 MPa (10,000 psi)

|

42 MPa (6,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

35 MPa (5,000 psi)

|

|

Setting

|

Wireline

|

Hydraulic

|

Mechanical

|

Hydraulic

|

Mechanical

|

|

Application

|

Set Bridge Plug,

Production Packer or

Cement Retainers

|

Set Bridge Plug,

Production Packer or

Cement Retainers

|

Set Bridge Plug,

Production Packer or

Cement Retainers

|

Anchor Tubing

|

Plugging Tubing

|

|

Model

|

Open Hole Packer

|

Frac Sleeve

|

Stinger/Centralizer

|

Anchor/Expansion Joint

|

Cement Head

|

|

Size

|

6.5Ą±

|

6.5Ą±

|

4 1/2Ą±-16Ą±

|

5 1/2Ą±-9 5/8Ą±

|

2 7/8Ą±-20Ą±

|

|

Temperature

|

148ĄăC (300ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

148ĄăC (300ĄăF)

177ĄăC (350ĄăF)

|

___

|

|

Pressure

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

70 MPa (10,000 psi)

|

___

|

|

Setting

|

Hydraulic/Oil

|

Hydraulic

|

___

|

___

|

___

|

|

Application

|

Open Hole Plugging

|

Fracturing, Acidizing

|

Cementing Operation

|

Testing, Fracturing,

Acidizing, Production,

Workover

|

Well Cementation

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|