|

| We supply API certified oilfield drilling rigs, workover rigs, drawworks, wire rope, drill line, DC motor, AC motor, YM Hydranlic Catheads, ZP series rotary table, hydraulic winches, air winches, hydraulic power units, rotary hoses, crown block, sheave, traveling block, hooks, deadline anchor, top drive spare parts, drill pipe elevator, casing elevator, drill collar elevator, tubing elevator, sucker rod elevator, slip type elevator, single joint elevator, SE spider, links, perfection link, manual tong, casing tong, dies, power slip, manual slip, Kelly bushing, iron roughneck, power tong, hydraulic power tong unit, Kelly spinner, ram BOP, annular BOP, diverter, BOP control system, BOP control line, Conflex hose, spacer spools, adapter spools, double studded adapter flanges, drilling spool, choke and kill manifold, gate valves , butterfly valves, shale shakers, screens, desander, Centrifugal pumps, Vacuum degassers, Mud cleaners, Desilters, Shearing pumps, Centrifuges, Agitators, Mixing pumps, Poorboy degasser/Mud gas separator, screw pump, Venturi hopper, Submersible slurry pump, Flare igniter, Mud gun, Mud tanks, F-Series Triplex Mud Pump, 3NB Series Triplex Mud Pump, Unitized Mud Pump Package, Mud pump Spare parts such as Discharge Filter Assembly, Clamp of Mud Pump, Piston Assembly, Cylinder Head and Valve Cover, Guide plate, Plug Board Assembly, Air chamber assembly, Shear Relief Valve, Liner of Mud Pump, Cross Head of Mud Pump and Other parts Liner hanger, Cement head, Float collar and float shoe, Cementing plug, Casing Packer, Casing Centralizer, Mill shoe, Stop collar, Double pump cementing units, fracturing pumping units, Completion tools, pumping units, sucker rods, sucker rod pumps, screw pumps, submersible motors, X-mas tree, tubings, drill pipes, drill collars, heavy weight drill pipes, Kelly, stabilizers, drilling jars, bit subs, X-over subs, hole openers, casing and tubing drifts, casing scrapers, drilling instrument and electrical System, oilfield camp houses, drilling instrumentation and electrical system. Please send email to us if you need any information. |

|

| Gate valve |

|

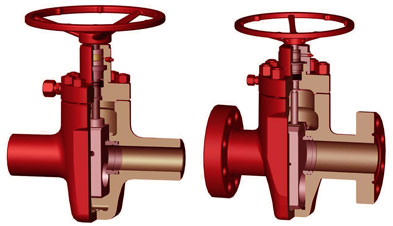

DEMCO GATE VALVE

DM GATE VALVE(Interchangeable with Demco Model DM Gate Valve) DM GATE VALVE(Interchangeable with Demco Model DM Gate Valve)

The DM Gate Valve, are solid gate, rising stem, gate valves with resilient seals. They are purpose made for mud, cement, fracturing and water service and are easy to operate and simple to maintain.

Features:

- Designed specifically for Abrasive and Erosive use

- All Valves Have Stainless Steel Stems

- API 6A PSL 1, 2 and 3 available

- Gates can be supplied in Nickel-Plated Carbon Steel, Monel, Aluminum Bronze or Stainless Steel

- Stainless or Carbon Steel Inserts with Nitrile or HNBR Elastomer

- Factory Pressure Tested in Accordance with API 6A

- Can be supplied with Flanged End Connections, Hammer Union Ends, Threaded Connections or Butt Weld Ends

- Available with Pressure Ratings up to 5,000 psi in 2", 3", 4", 5" x 4" and 6" x 4" Valve Sizes

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Body

|

1

|

4130

|

|

2

|

Bonnet Seal

|

1

|

NBR

|

|

3

|

Seat

|

1

|

Steel+NBR

|

|

4

|

Gate

|

1

|

410

|

|

5

|

Down Stop Ring

|

1

|

Steel

|

|

6

|

Stem

|

1

|

410

|

|

7

|

Bonnet

|

1

|

4130

|

|

8

|

Body Stud

|

4

|

4140

|

|

9

|

Body Nut

|

4

|

1045

|

|

10

|

Stem Seal Assy.

|

1

|

Assy.

|

|

11

|

Retainer

|

1

|

Steel

|

|

12

|

Secondary Seal

|

1

|

NBR

|

|

13

|

Stem Screw

|

1

|

Steel

|

|

14

|

Key

|

1

|

Steel

|

|

15

|

Bearing

|

2

|

TEFLON

|

|

16

|

Lube Fitting

|

1

|

Assy.

|

|

17

|

Screw Housing

|

1

|

Steel

|

|

18

|

Bonnet Stud

|

2

|

4140

|

|

19

|

Bonnet Nut

|

2

|

1045

|

|

20

|

Stem Screw Seal

|

1

|

NBR

|

|

21

|

Handle Assy.

|

1

|

Steel

|

|

22

|

Tube

|

1

|

Clear Acrylic

|

|

23

|

Stem Protector

|

1

|

Ductile Iron

|

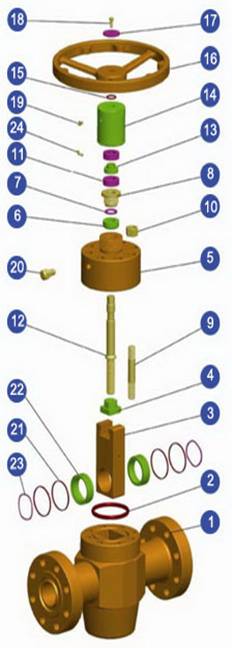

RISING STEM SLAB GATE VALVE

Features: Features:

Non-rising stemŁŹcompact structure , space savingŁŹavailable with flange and thread connection

Full bore design eliminates efficiently pressure drop and vortex, and eliminates washing by solids in fluid

Metal-to-metal seal is used between bonnet and body, gate and seat, body and seat

The surface of gate and seat is weld overlay with hard alloy, which has feature of corrosion resistance and washing resistance

The bonnet and stem designed with back seal, can replace stem seal ring under pressure

One side of bonnet is designed with sealant injection in order to supply sealant and improve seal and lubrication performance of gate and seat

Working PressureŁș2000Psi~20000Psi

Nominal BoreŁș1-13/16Ą±~9Ą±Łš46mm~230mmŁ©

Working mediumŁșoil, natural gas, and mud

Working temperatureŁș-46Ąæ~121ĄæŁšClass L~UŁ©

Material ClassŁșAAĄąBBĄąCCĄąDDĄąEEĄąFFĄąHH

Specification levelŁșPSL1~PSL4

Performance RequirementsŁșPR1~PR2

Comforms to API 6A

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Body

|

1

|

4130

|

|

2

|

Bonnet Seal Ring

|

1

|

1010

|

|

3

|

Gate

|

1

|

4130

|

|

4

|

Gate T-Nut

|

1

|

5140

|

|

5

|

Bonnet

|

1

|

4130

|

|

6

|

Stem Lip Packing

|

1

|

NBR

|

|

7

|

Packing Ring

|

3

|

410

|

|

8

|

Packing Gland

|

1

|

4130

|

|

9

|

Bonnet Stud

|

8

|

4130

|

|

10

|

Bonnet Nut

|

8

|

5140

|

|

11

|

Bearing

|

2

|

Assy.

|

|

12

|

Stem

|

1

|

410

|

|

13

|

Split Busing

|

1

|

5140

|

|

14

|

Bearing Cap

|

1

|

5140

|

|

15

|

O-ring

|

1

|

NBR

|

|

16

|

Handwheel

|

1

|

1035

|

|

17

|

Wahser

|

1

|

1035

|

|

18

|

Screw

|

1

|

1035

|

|

19

|

Oil Cup

|

1

|

Assy.

|

|

20

|

Grease Fitting

|

1

|

Assy.

|

|

21

|

O-ring

|

4

|

NBR

|

|

22

|

Seat

|

2

|

4130

|

|

23

|

Wave Spring

|

2

|

410

|

|

24

|

Lock Screw

|

3

|

Steel

|

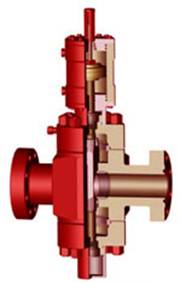

NON-RISING STEM SLAB GATE VALVE

Features: Features:

- Full bore design eliminates efficiently pressure drop and vortex, eliminates washing by solids in fluid.

- Mental-to-mental seal is used between bonnet and body, gate and seat, seat and body.

- The surface of gate and seat is welding overlay with hard alloy, which has feature of corrosion resistance and washing resistance.

- The balanced stem can balance the stem load, reduce load of stem thread and bearing to decrease operating torque.

- The bonnet and stem are designed with back seal, which can replace stem sealing under pressure.

- One side of bonnet is designed with sealant injection valve.

- Rising stem structure can indicate open and close of valve.

- Complete with different pneumatic (hydraulic) actuator upon userĄŻs requirements.

- Working Pressure: 2000PSIĄ«20000PSI

- Nominal Bore: 1.13/16"Ą«9" (46mmĄ«230mm)

- Working Medium: oilĄąnatural gasĄąmud and gas containing H2SĄąCO2

- Working Temperature: -46ĄăCĄ«121ĄăCŁšClass LUŁ©

- Material Class: AAĄąBBĄąCCĄąDDĄąEEĄąFFĄąHH- Specification level: PSL1-4

- Performance Requirement: PR1-2

- Comforms to API 6A

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Body

|

1

|

4130

|

|

2

|

Seat

|

1

|

1010

|

|

3

|

O-ring

|

1

|

4130

|

|

4

|

Gate

|

1

|

5140

|

|

5

|

Stem

|

1

|

4130

|

|

6

|

Bonnet Seal Ring

|

1

|

NBR

|

|

7

|

Grease Fitting

|

3

|

410

|

|

8

|

Bonnet

|

1

|

4130

|

|

9

|

Bonnet Stud

|

8

|

4130

|

|

10

|

Bonnet Nut

|

8

|

5140

|

|

11

|

Packing

|

2

|

Assy.

|

|

12

|

Packing Gland

|

1

|

410

|

|

13

|

Stem Nut

|

1

|

5140

|

|

14

|

Bearing

|

1

|

5140

|

|

15

|

Bearing Cap

|

1

|

NBR

|

|

16

|

Lock Screw

|

1

|

1035

|

|

17

|

Oil Cup

|

1

|

1035

|

|

18

|

Handwheel

|

1

|

1035

|

|

19

|

Stem Protector

|

1

|

Assy.

|

HYDRAULIC PLATE VALVE

Features

The opening and closing mechanism of hydraulic plate valve takes hydraulic control manner, so that it is very convenient for using to automatic control system and remote control.

Technical parameters:

- Pressure rating: 2000Ą«15000psi

- Nominal size: 1 13/16" Ą« 4 1/16"

- Operating temperature: P U

- Property rank: PR1-2

- Specification level: PSL 1-3

- Materiel class: API 6A AA - FF

- Operating pressure : 107Ą«1500psi

|

Item

|

Component

|

Qty.

|

Material

|

|

1

|

Body

|

1

|

35 CrMo

|

|

2

|

Gate

|

1

|

35 CrMo

|

|

3

|

Seat

|

2

|

35 CrMo

|

|

4

|

Wave Spring

|

2

|

2Cr13

|

|

5

|

O-Ring

|

4

|

NBR

|

|

6

|

Bonnet Stud

|

8

|

35 CrMo

|

|

7

|

Stem

|

1

|

2Cr13

|

|

8

|

Bonnet

|

1

|

35 CrMo

|

|

9

|

Packing Gland

|

1

|

35 CrMo

|

|

10

|

Screw

|

20

|

|

|

11

|

Lower Gland

|

1

|

35 CrMo

|

|

12

|

O-Ring

|

2

|

NBR

|

|

13

|

O-Ring

|

2

|

NBR

|

|

14

|

Cylinder

|

1

|

35 CrMo

|

|

15

|

Piston

|

1

|

35 CrMo

|

|

16

|

Lock Nut

|

1

|

40Cr

|

|

17

|

Upper Gland

|

1

|

35 CrMo

|

|

18

|

Indicator Rod

|

1

|

2Cr13

|

|

19

|

Stem Protector

|

1

|

Q235

|

|

20

|

O-Ring

|

2

|

NBR

|

|

21

|

O-Ring

|

2

|

NBR

|

|

22

|

O-Ring

|

2

|

NBR

|

|

23

|

O-Ring

|

2

|

NBR

|

|

24

|

Plug

|

2

|

45

|

|

25

|

Bonnet Nut

|

8

|

40Cr

|

|

26

|

Packing Ring

|

2

|

2Cr13

|

|

27

|

Stem Lip Packing

|

5

|

FKM

|

|

28

|

Grease Fitting

|

1

|

|

|

|

PreviousŁș

NextŁș

Back |

|

| VisitŁș timeŁș2017/4/19 ĄŸPrintĄż ĄŸcloseĄż |

|

|

|

|